St. Paul, MN (July 23, 2020) — With Matsuura’s LUMEX technology, Deep Ribs and Conformal Cooling Channels significantly reduce product cycle time.

St. Paul, MN (July 23, 2020) — With Matsuura’s LUMEX technology, Deep Ribs and Conformal Cooling Channels significantly reduce product cycle time.

Matsuura features multiple customer case studies, all showing 25% to 45% reductions in cycle time reductions.

Customers understand the value in implementing additive manufacturing technology into their tools. These include conformal cooling channels, porous venting, and virtually no concerns over deep ribs.

With this transformative quick-turn manufacturing, customers now maintain the ability to build a production tool in days versus weeks or months, with reduced tooling costs. Those toolmakers, who are also injection molders, are reaping the additional benefits of cycle time savings, thanks to an additively manufactured mold’s far greater cooling capabilities.

According to Peter Zelinski, Editor-In-Chief of Additive Manufacturing Magazine, one of the most significant impacts of metal additive manufacturing is on plastic part production and conformal cooling, using additive manufacturing to build conforming cooling channels into an injection mold component. More effective cooling potentially means seconds per part shaved from the injection molding cycle, the cycle making a plastic part.

“Now seconds for part might not sound like much, but multiply that across millions of parts that might be made through injection molding that might be made using a tool like this and the result could be production so much faster that fewer injection molding presses would be made to achieve the same production in the same amount of time,” said Zelinski.

Watch the video:

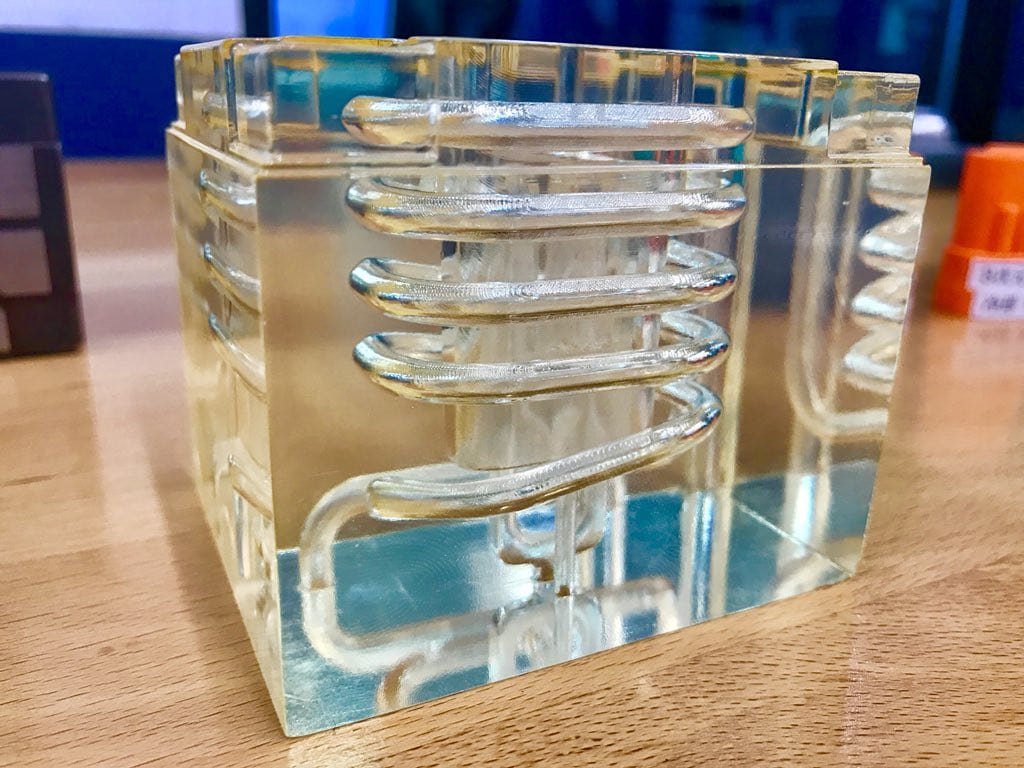

Custom Mold & Design added to its product offerings and expanded into additional industries with the purchase of a Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine. This powder bed metal additive manufacturing platform with subtractive machining capability produces accurate parts from melted and laser sintered melted powders, while precisely high-speed milling surfaces. This technology enables the ability to “grow” a metal component in layers with complex internal features.

Conformal-cooled injection mold-tool inserts produced with this hybrid process incorporate complex curved, shaped or spiral cooling channels and can be formed in small, narrow or awkwardly-shaped inserts. The result is mold tools with consistent and accurate cooling across the entire forming area, even within small or complex-shaped pockets. This technology also eliminates distortion problems and poor part quality from inefficient cooling, improving cycle times, part yields and initial part quality by utilizing the powder bed fusion process’s variable porosity capabilities to assist in venting mold gases in the flow front.

Read more about Custom Mold & Design HERE.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura LUMEX products, contact: [email protected].

St. Paul, MN (July 24, 2020) — Matsuura Machinery USA, an innovator in the development of high-speed machining and the manufacture of automated, […]

St. Paul, MN (July 24, 2020) — Matsuura Machinery USA, an innovator in the development of high-speed machining and the manufacture of automated, […]