St. Paul, MN (February 17, 2019) — According to Michael Guckes, Chief Economist, Gardner Intelligence, the Gardner Business Index (GBI) showed improved production in manufacturing.

St. Paul, MN (February 17, 2019) — According to Michael Guckes, Chief Economist, Gardner Intelligence, the Gardner Business Index (GBI) showed improved production in manufacturing.

Registering 53.9, GBI began the new year indicating improved business conditions after posting a series of slowing growth signals during the final quarter of 2018. This latest result raises the Index back into the range of growth readings from earlier in the current business cycle. Over the last two years, the GBI has averaged a reading of 56.1, including a historically high reading of 60.1 in February of 2018. As a result of the Index’s climb towards its all-time high a year ago, the latest reading compared is down 7.0 percent from a year ago. Gardner Intelligence’s review of the underlying data for the month indicates that the Index – calculated as an average – was supported by production, supplier deliveries and new orders. The components which lowered the Index included employment, backlog and exports. Only exports reported a contractionary reading during the month.

For the first time since April of 2018, production expanded faster than supplier deliveries, with the reading for production increasing markedly while the expansion in supplier deliveries slowed. This intersecting of the two readings may be an early indicator that supply chains are close to being – or have become – balanced with current levels of production. This change comes after supplier delivery readings spent most of 2018 attempting to catch up with the unusually strong rise in new orders, which peaked in early 2018 and has been highly elevated by historical standards since early 2017.

The net effect of January’s expansionary reading for new orders combined with further weakness in exports and no change in backlogs implies that domestic demand for manufactured goods continues at a minimum to offset reduced exports. Recent macroeconomic indicators in both Asia and Europe have indicated slowing and even contracting economies making domestic consumption critical to the sustained expansion of U.S. manufacturing.

The fastest growing industries during the month were power generation, construction machinery, oil & gas, pumps/valves/plumbing products, aerospace, primary metals, hardware, medical, custom processors, machinery/equipment, industrial motors/hydraulic/mechanical components, petrol processors, automotive, plastics/rubber products, electronics/computers/telecommunications, and metalcutting job shops.

In addition to the overall durable goods index, Gardner Intelligence computes indices for several technologies or processes. For the month, Precision Machining, was the fastest growing technology; it was followed by Metalworking, Moldmaking, Plastics, Composites, and Finishing. All technologies expanded during the month.

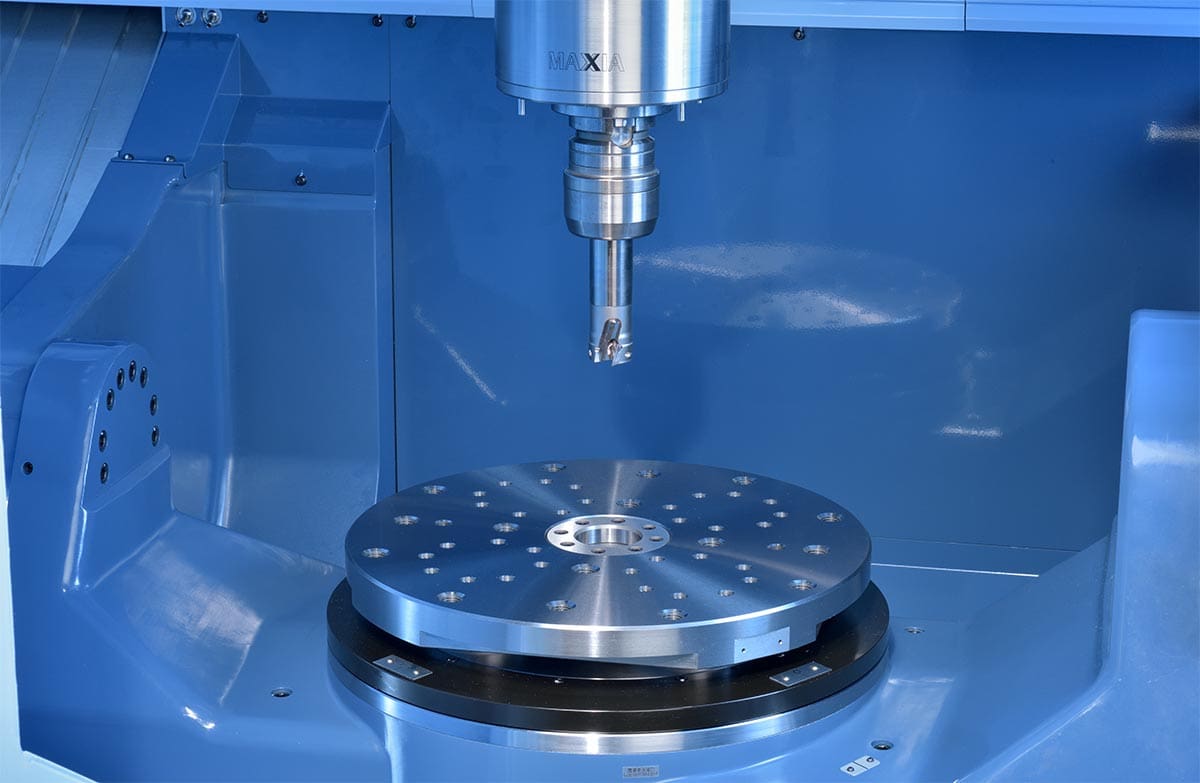

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected] or visit: www.matsuurausa.com.