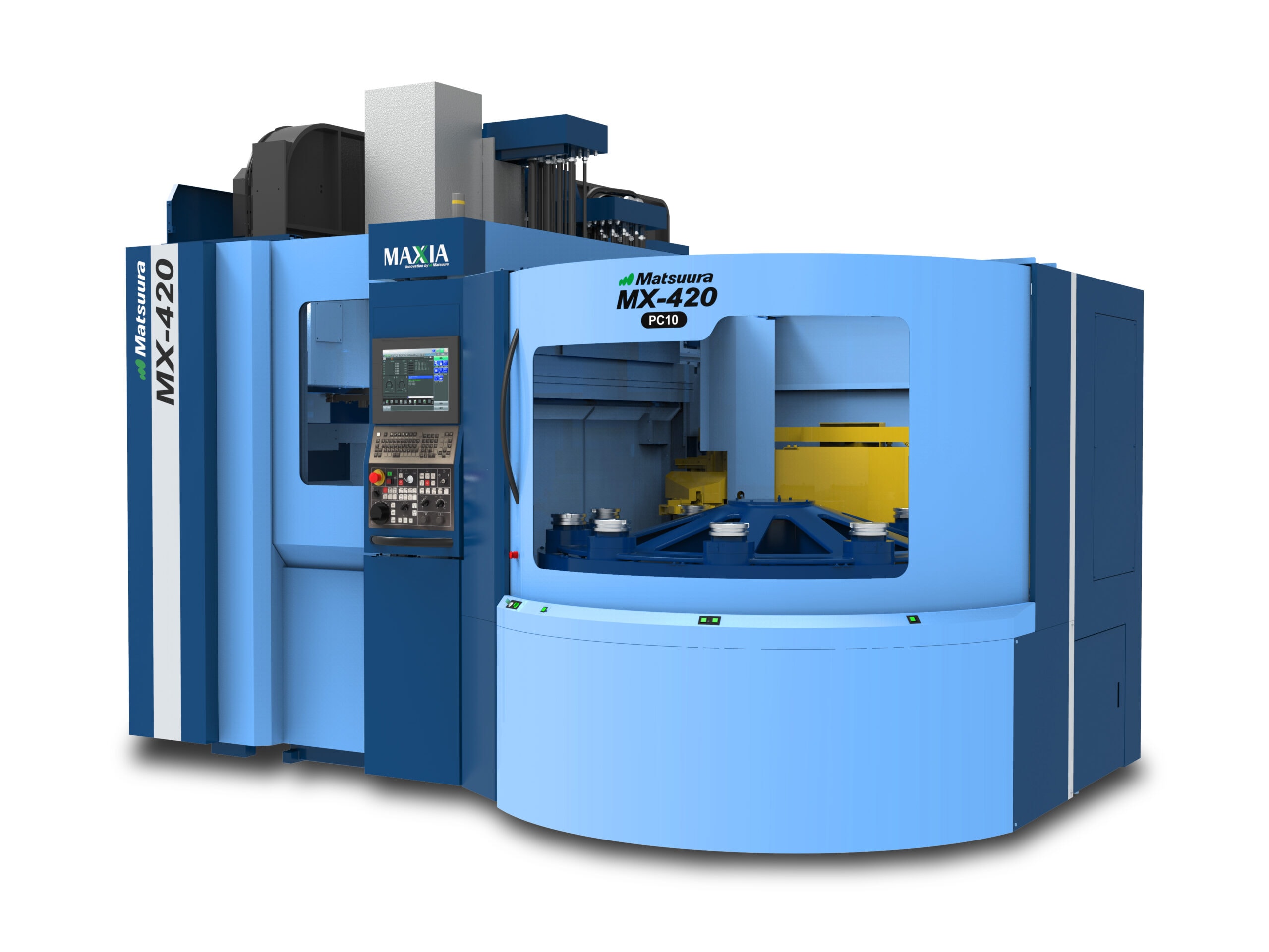

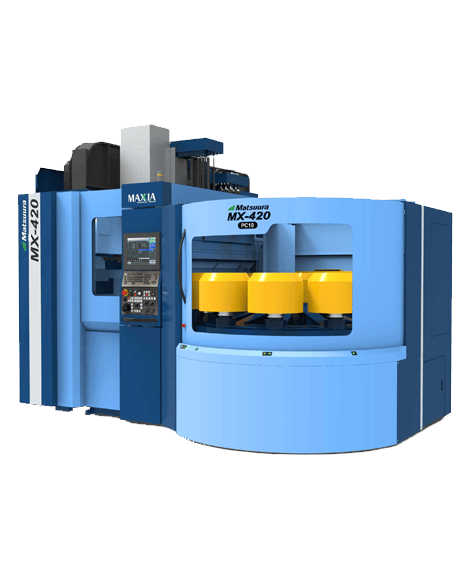

Following the global success of the MX-330 PC10, Matsuura introduced the MX-420 PC10 5-Axis Vertical Machining Center configured with 10 pallets and 90 tools. Possessing Matsuura’s legendary automation technology, the hand-built, fully [...]

All Models

MX-420

MX-420

PC10

5-Axis Vertical | Machining Center

Automated Operation |

High Precision |

Compact Size |

Maximize your workspace, easily swap pallets, and achieve 85% uptime with the MX-420 PC10. Compact yet efficient, the MX-420 PC10 features an ergonomic design and Matsuura’s extended unmanned automation.

Product Details

The MX-420 PC10 is configured with 10 pallets and 90 different tools, making it a uniquely efficient machine with a minimal size. It also works in tandem with the MAM72-35V and MX-330, with easily transferable pallets that can be used across platforms.

Quick Specs

| Max Work Size mm (in) |

ø330 × H300 (Ø12.99×H11.81) | ø420 × H300 (ø16.54×H11.81) |

|---|---|

| Spindle Speed RPM |

15,000:BT40 Standard | 15,000PowerUp | :BT40 | 20,000:BT40 |

| Travel (x/y/z) mm (in) |

435/465/560 | (17.13/18.31/22.05) |