St. Paul, MN (October 26, 2018) --- Matsuura Machinery USA, an innovator in the development of high-speed machining and the manufacture of automated, unmanned high accuracy CNC machine tools, announces [...]

All Models

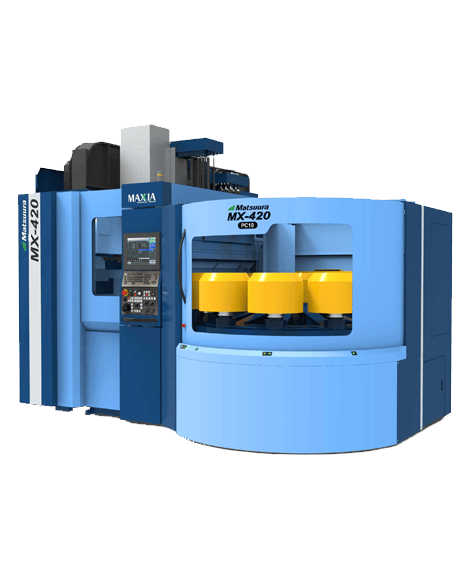

MX-850

MX-850

PC4

5-Axis Vertical | Machining Center

Cost Effective |

Repeatability |

Ergonomic Design |

With the MX-850 PC4, creating accurate parts requires less time and effort than ever before. Its compact, ergonomic design saves space, reduces training time, and improves productivity.

Product Details

Compatible and compact, the MX-850 PC4 features a huge work envelope in a space-saving frame. High rigidity and repeatability ensure that production is carried out with precision and speed.

Industries

Technology

Quick Specs

| Max Work Size mm (in) |

Ø850×H450 | (Ø33.46×H13.77) | Ø850×H385 | (Ø33.46×H13.77) *with pallet options |

|---|---|

| Spindle Speed RPM |

12,000:BT40 Standard | 15,000:BT40 | 20,000:BT40 |

| Travel (x/y/z) mm (in) |

900/780/650 | (35.43/30.70/25.59) |