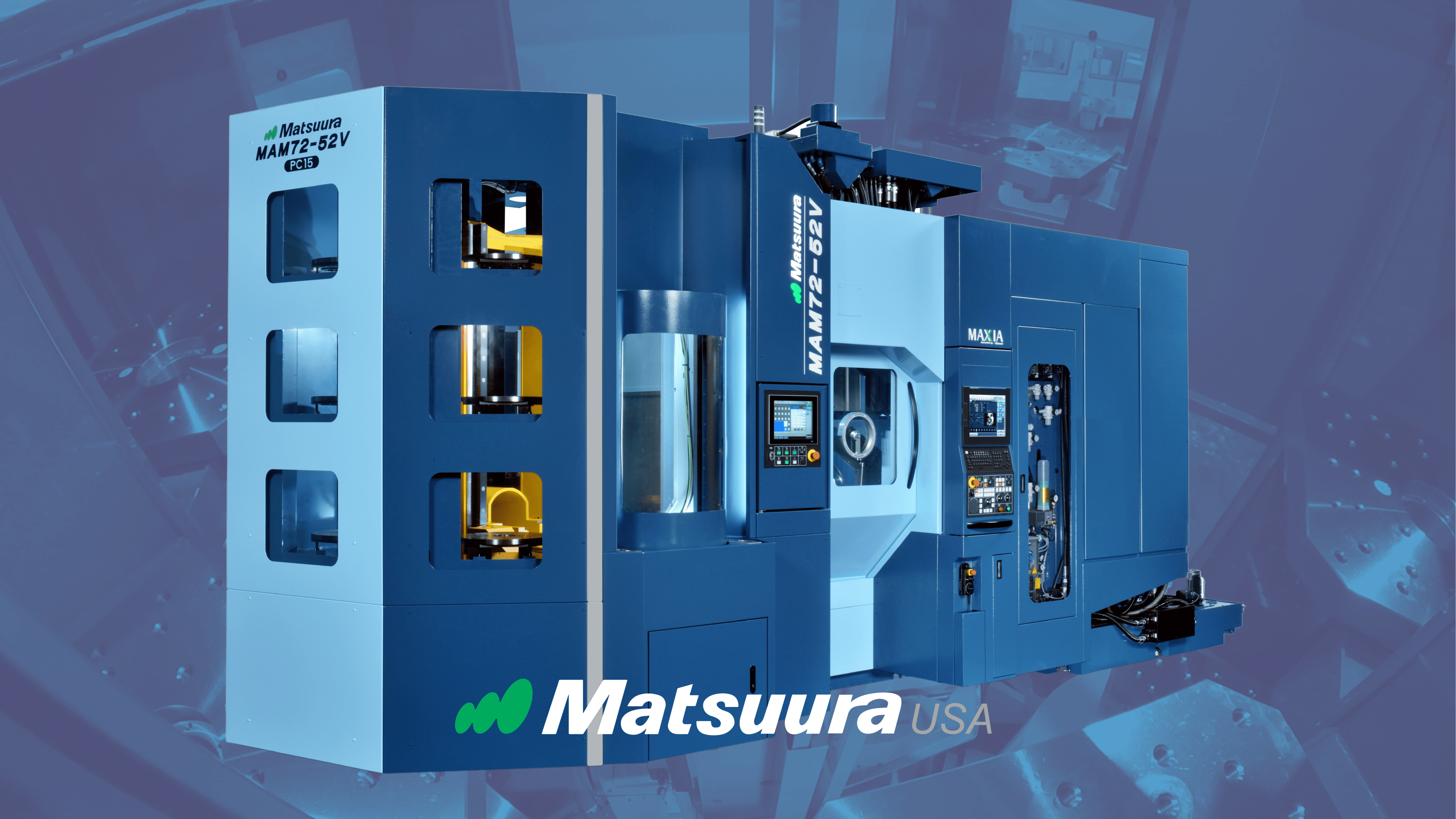

St. Paul, MN (October 16, 2018) --- Matsuura Machinery USA, an innovator in the development of high-speed machining and the manufacture of automated, unmanned high accuracy CNC machine tools, announces [...]

All Models

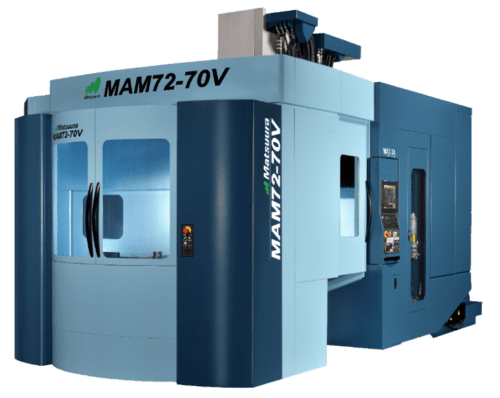

MAM72-70V

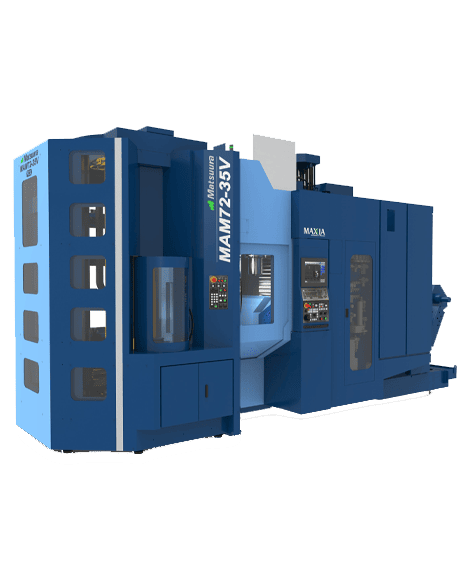

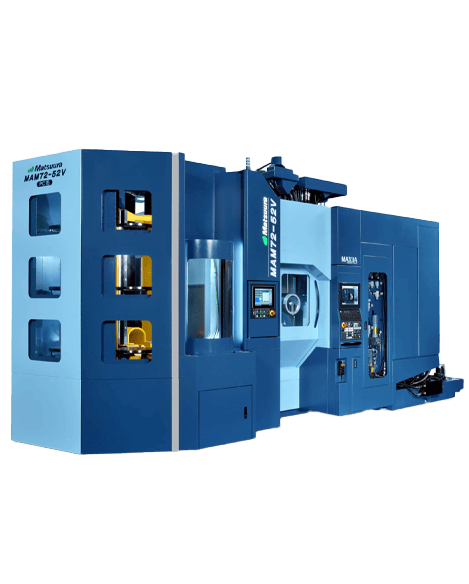

5-Axis Vertical | Machining Center

Automated Operation |

Palletized Versatility |

Speed & Precision |

Designed with a large pallet and tool changer, the MAM72-70V is as versatile as it is efficient. Its high accuracy, repeatability, and unmanned operation support high mix, low volume production.

Product Details

The MAM72-70V has the largest work envelope of any Matsuura 5-axis vertical machine. With numerous automation options and the ability to sustain continuous production for up to 72 hours, it can handle demanding production needs day and night.

Quick Specs

| Max Work Size mm (in) |

Standard | Ø700×H500 | (Ø27.56×H19.68) |

|---|---|

| Spindle Speed RPM |

15,000:BT40 Standard | 15,000 RPM Power Up BT40 | 20,000:BT40 |

| Travel (x/y/z) mm (in) |

1200/720/710 | (47.24/28.34/27.29) |