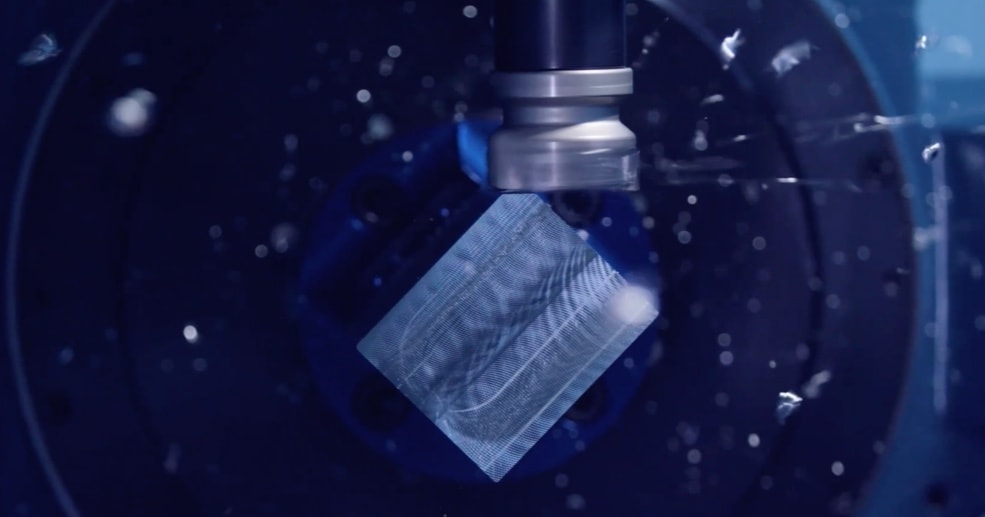

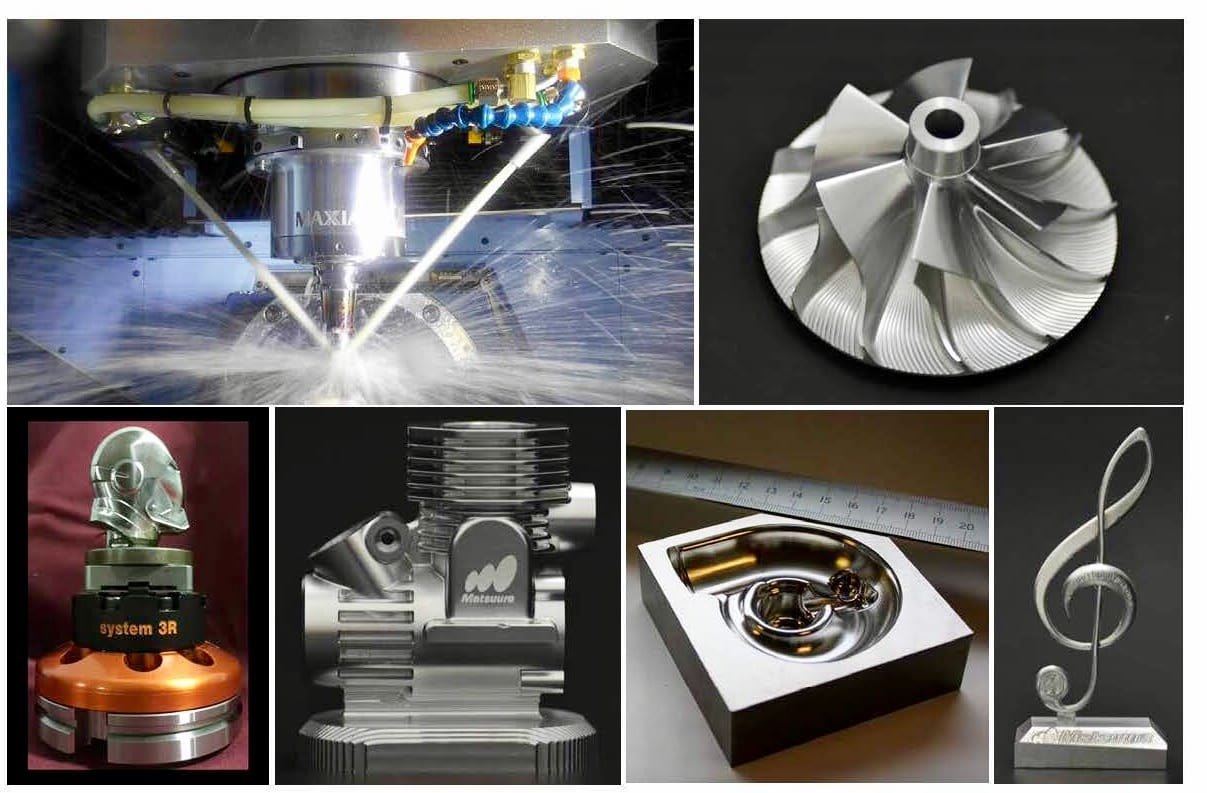

https://youtu.be/1_hwupOxdI4 Watch as Elliott Matsuura's Terry Beckwith explains the features and capabilities of the LX-160 Linear Motor Machine. The Matsuura LX-160 High Speed Linear Motor Machine is the ultimate 5-axis vertical machine [...]

All Models

LF-160

5 AXIS VERTICAL | Machining Center

High Speed |

Small Footprint |

Automated Operation |

The LF-160 delivers high accuracy in a compact footprint. Its high-speed spindle and multiple pallet options allow for high production and extended life of small diameter tools.

Product Details

The LF-160 features the highest number of pallets in a 5-axis machine and an ultra-low vibration spindle, ensuring expert precision and exceptionally high accuracy with every run. It’s the ideal machine for small or delicate parts, such as medical devices and implants.

Industries

Technology

Quick Specs

| Max Work Size mm (in) |

Standard | Ø160×H230 | (Ø6.29×H9.05) | [with PC] | Ø160×H200 | (Ø6.29×H7.87) *Bullet shape |

|---|---|

| Spindle Speed RPM |

46,000:BT30 Standard | 46,000:HSK-E40 |

| Travel (x/y/z) mm (in) |

500/250/300 | (19.68/9.84/11.81) |