St. Paul, MN (September 18, 2020) –St. Paul, MN — (Shop Metalworking Technology)

St. Paul, MN (September 18, 2020) –St. Paul, MN — (Shop Metalworking Technology)

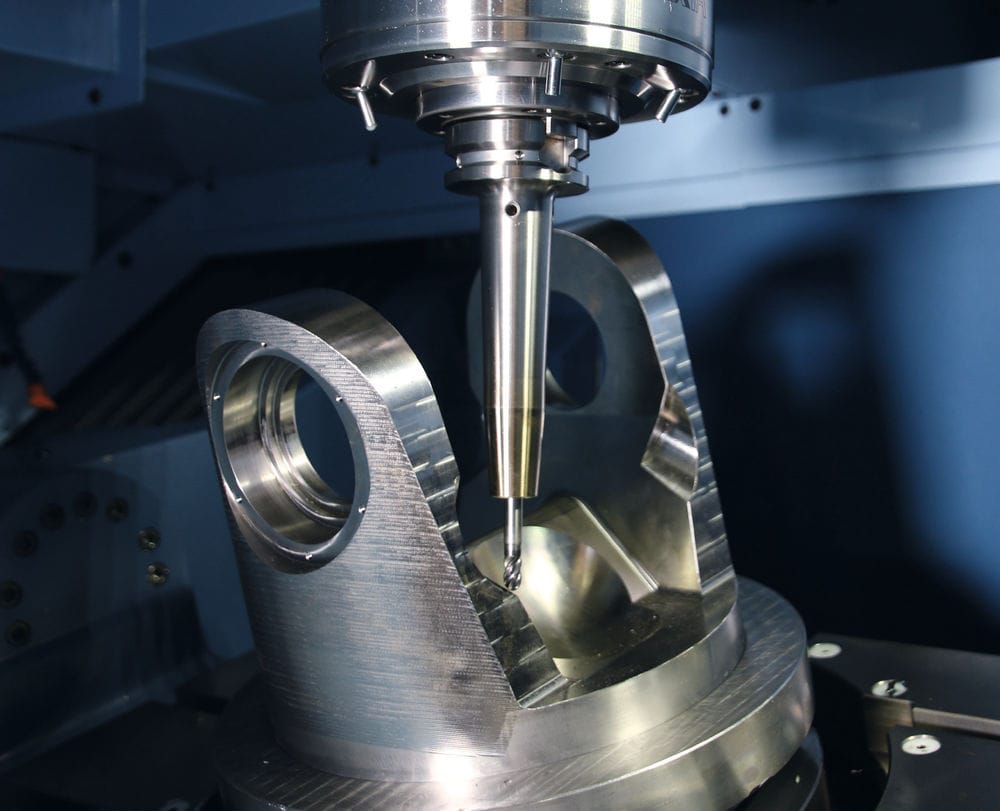

A steady increase in complex machining work led Camatech Inc., a supplier to the alternative fuel, general industrial and aerospace markets, to the purchase of two Matsuura five axis machines acquired from Elliott Matsuura in 2010 and in 2011.

The Acton, ON, manufacturing business, formed in 2000, operates out of a 13,000 sq. ft facility which houses other machining centers from Matsuura and the two MX-520 5 axis machining centers.

“We’re machining more complex parts that need a done-in-one type of machining to reduce set-ups and that’s why we went with the 5-axis machining process,” says Paul Culumovic, vice president. “We have other machines, including other Matsuura’s and they’re reliable machines with little downtime.”

Culumovic adds the machinists in his shop are comfortable with the Matsuura machines because they have worked on them for several years. “The controls are the same and although the software program is a little different—it’s more user friendly—at the end of the day it’s a Matsuura and our employees know how to work with this machine.

The machine is also better ergonomically designed, says Culumovic.

“It’s easy to load and unload the parts; you can step into the machine and load the parts, so during setup you don’t need to be a contortionist.”

While Camatech likes the design of the machines, it is the productivity gains of five axis machining that cinched the decision to purchase them. Five axis gives the company the ability to machine a variety of parts from simple to complex faster and in one set-up.

The two 12,000 rpm Matsuura machines are 5-axis vertical machining centers that can hold workpieces up to 520 mm in diameter by 350 mm in height. Machine load is made easier because of the 385 mm distance from the machine door to the table center and a front door opening width of 805 mm.

X, Y and Z axis travels are 630 mm, 650 mm and 510 mm respectively. The rapid traverse rate in X, Y and Z axes is 30m/min. In the A axis it is 10 min-1 and in the C axis it’s 25 min-1.

New to these machines is several support functions that are now standard but were optional in the past. Among them is a collision avoidance system, Intelligent Protection System (IPS), and the new generation operation system, the Matsuura Intelligent Meister System (MIMS).

With high-precision, performance, speed, accuracy, and reliability, the MX-520 provides a simple, effortless and cost-effective transition for 3-Axis users making the transition to full 5-Axis operation. The MX-520 is the superior machine for high precision, high production applications, high mix/low volume, & expensive or difficult to machine materials.

Designed with a RAM type structure, which offers a compact and highly rigid machining platform. The machine guarantees high rigidity, as well as, a generous machining envelope with excellent operability. The MX-520 also offers an assortment of configurations, which are ideal for all applications, all industries, and all materials.

The MX-520 has a compact footprint and outstanding ergonomic design, allowing rapid set-up and processing of complex parts.

The Matsuura MAXIA 12,000 RPM high-torque spindle is standard. A high-torque (187.0 Nm) motor is available to machine hard-to-cut materials. Matsuura’s 20,000 min-1 (108.7 Nm) spindle for high-speed machining of aluminum parts is available as an option.

CAMplete TruePath comes standard on all Matsuura 5-Axis Machines. The easy-to-use application that takes you from your CAM System to your Matsuura 5-Axis machine efficiently and safely. TruePath’s customizable post-processor allows you to output your NC programs the way you need, with no on-machine editing required. 5-axis simulation, visualization and verification tools give you the confidence of knowing how your machine will behave before you run a single line of G-code.

Contact your exclusive Matsuura Distributor to learn more. Find your distributor HERE.

For more information on Matsuura products in Canada, please contact Elliott Matsuura Canada, Inc. at elliottmachinery.com.

Camatech Inc. was established in May of 2000 and has since become a key supplier of Alternative Fueling and Aerospace components to several High Technology companies in North America.

The three principles of Camatech Inc. bring a baseline of experience to the company, which extends over a 35-year period with extensive exposure to the Aerospace, Medical and Industrial sectors.

Camatech’s automated manufacturing software provides detailed real time tracking of customer orders throughout the production cycle. Key operations are scanned and recorded providing part production history and traceability and are available upon request.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected].