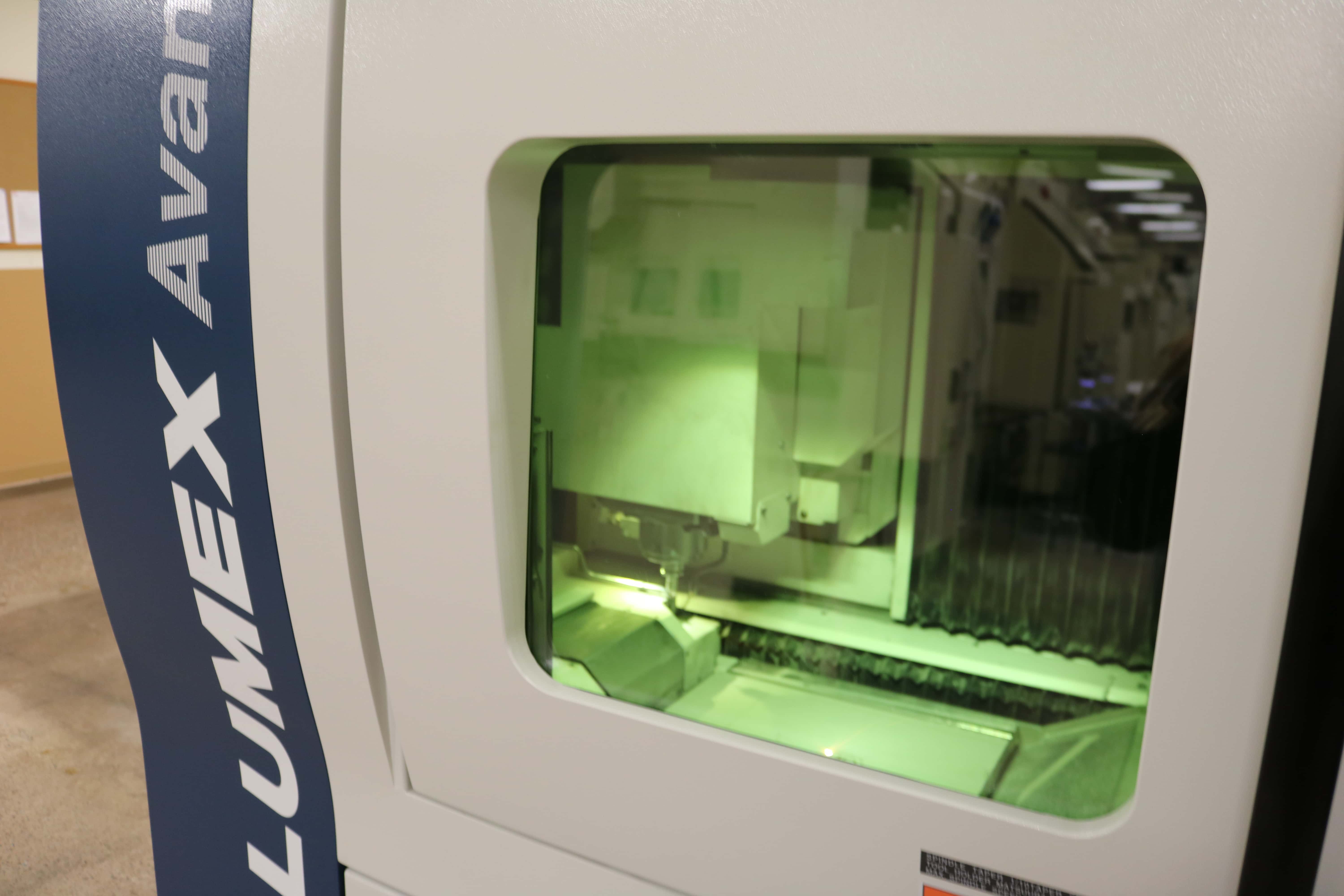

St. Paul, MN — (May 22, 2019) Custom Mold & Design adds to its product offerings with the purchase of a Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine, a powder bed metal additive manufacturing platform with subtractive machining capability.

St. Paul, MN — (May 22, 2019) Custom Mold & Design adds to its product offerings with the purchase of a Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine, a powder bed metal additive manufacturing platform with subtractive machining capability.

The machine produces accurate parts from melted and laser sintered melted powders, while precisely high-speed milling surfaces. This technology enables the ability to “grow” a metal component in layers with complex internal features.

Conformal-cooled injection mold-tool inserts produced with this hybrid process incorporate complex curved, shaped or spiral cooling channels and can be formed in small, narrow or awkwardly-shaped inserts. The result is mold tools with consistent and accurate cooling across the entire forming area, even within small or complex-shaped pockets. This technology also eliminates distortion problems and poor part quality from inefficient cooling, improving cycle times, part yields and initial part quality by utilizing the powder bed fusion process’s variable porosity capabilities to assist in venting mold gases in the flow front.

Read more at: https://www.moldmakingtechnology.com/products/hybrid-milling-machine-improves-cycle-times-and-part-yields

Matsuura’s combination of additive and subtractive technologies enables the production of parts and component geometries in a method that has never been possible or imagined. Often referred to as a “one machine, one process” system, the Matsuura LUMEX series permits production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. These machines possess both high-speed milling and laser sintering capability.

The Matsuura LUMEX serves predominantly the high value, high accuracy mold and die market. Dies and molds with very complex geometries can be fabricated in one piece with high accuracy, shortening lead time and reducing manufacturing costs to a half or even a third of conventional methods.

Differentiated original parts and mold production with internal structures, thus far considered impossible, are achievable on the Matsuura LUMEX machines. The Matsuura LUMEX metal laser sintering hybrid milling machine is capable of quick turn production of custom parts and molds, whether prototypes or small production run parts and molds

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected].