St. Paul, MN (May 15, 2019) — According to Craig St. John, President of Matsuura Machinery USA, Inc., investing in automation allows shops to stay globally competitive.

St. Paul, MN (May 15, 2019) — According to Craig St. John, President of Matsuura Machinery USA, Inc., investing in automation allows shops to stay globally competitive.

“Successful and surviving job shops are removing as much labor cost as possible from the process. The goal is to obtain as many hours of unmanned machining as possible,” St. John said.

With the shortage and the expense of skilled labor to operate CNC Machines, automation provides the potential for expanding production and increasing profit while decreasing employment costs.

“People usually think of automation in high volume production environments, typically with 6-axis robots, but automating the small lot size production common in the aerospace market is different and more challenging,” St. John said.

St. John explained how in small lot production; elimination of set-up time is the primary goal. Shaving a few seconds or even minutes of cycle time per part when making 20 or 30 parts is insignificant. The savings and the profit improvement come from reducing set-up time from hours to zero and by running parts unattended overnight and on weekends.

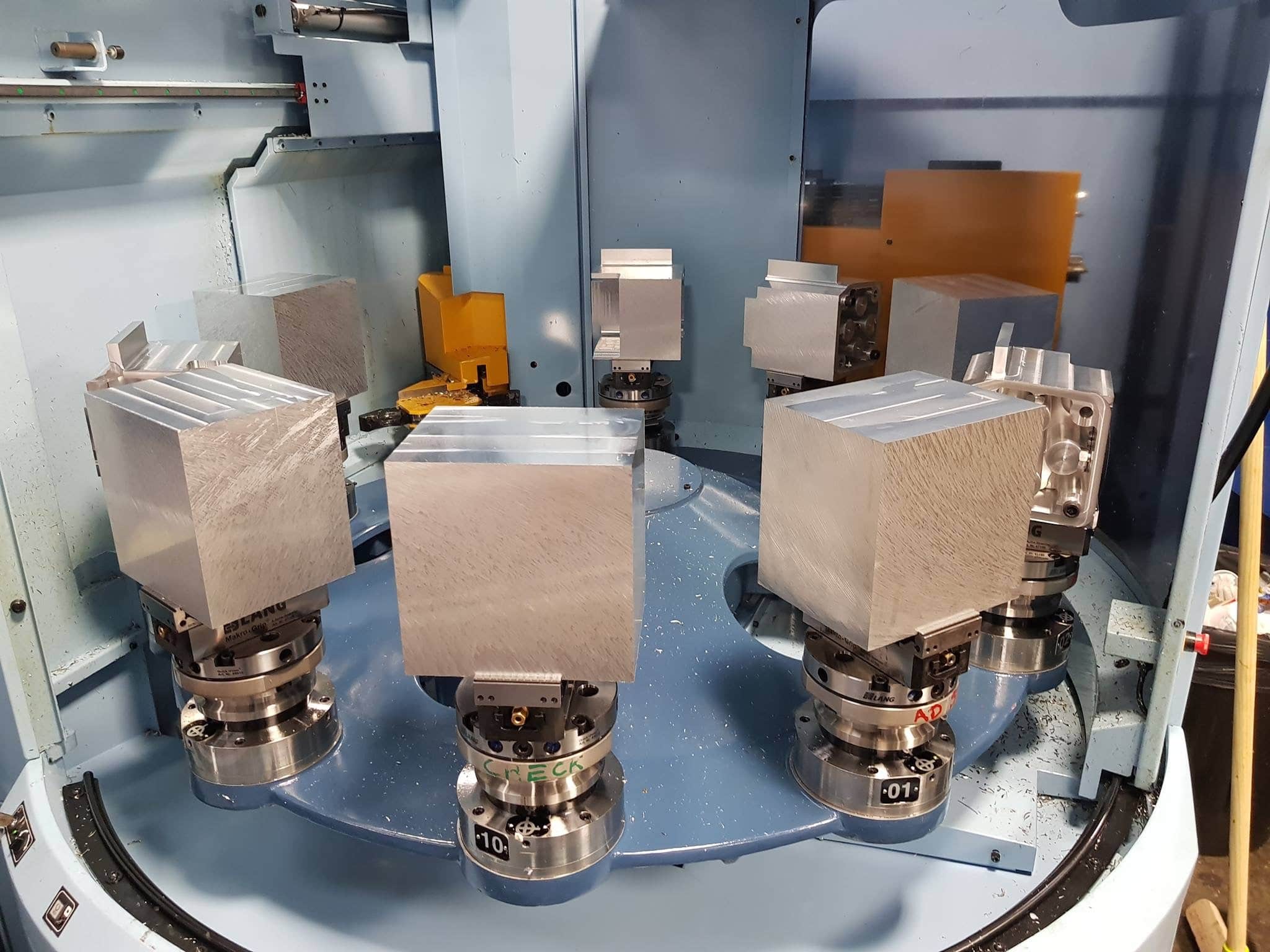

A key to this kind of operation is the machining of 5 sides of the part in a single work holding. Automation in the aerospace world requires palletization, simplified work holding, foolproof tool management, part probing, usually 5-axis machines and large tool changers.

Few machine tool builders have perfected this type of automation and the shops incorporating the technology have tremendous competitive advantages. Matsuura’s line of MAM72 models fit this application perfectly. MAM stands for Matsuura Automated Manufacturing and 72 is the hours in a weekend. The machines are built from the ground up to run unattended.

Regarding the implementation of automation, St. John says the real question is ‘can you afford not to streamline your business and reduce your labor and other costs?’

“If you make parts the same way your Dad did, the same way you did 5 years ago, you may hang onto your business for a few more years, but business expansion and nice profits will not be in your future,” he added.

Another way to effectively achieve automation is to combine operations. Machining 5 sides of a part along with angled holes and surfaces is essentially automation compared with flip flopping the same part through six or more separate operations.

This approach to reducing set-up time, reducing labor content and combining of operations does not need to be expensive, nor time intensive to implement. 5-axis machines today are simpler, less expensive, and easier to program than in years past.

“You may never do simultaneous 5-axis contours, but you are going to machine all sides of that billet. Why not do 5 sides in one set-up – that’s the key to improved part accuracy, lower fixturing costs, and reduced labor costs today,” St. John explained.

Investing in this level of automation allows shops to stay globally competitive.

Matsuura expanded its customer base and answered aftermarket demand for a smaller simpler 5-axis platform by developing a more cost-effective line of these machines with built-in automation as an option. Featuring the same hand-built quality, high speed and sustained precision as the fully automatic machines, the two newest machines in the MX series provide productive, versatile and affordable unmanned 5-axis production.

High volume simple part production like automotive parts are obvious targets for automation.

“It’s easy to automate a process that will be repeated a million times a year. However, in the world of aerospace, defense and for the most part medical, lot sizes are small and parts are complex, require close tolerances and excellent surface finishes,” St. John said.

Combining operations using 5-axis machining centers and running unmanned using pallet systems is equally effective in the medical component applications or any complex parts requiring close tolerances.

St. John describes three factors to consider when selecting automation solutions: Floorspace; Workpiece Size/Weight; Lot sizes: and Machine Flexibility.

In many areas of the country, rental space is a premium, and shops must consider their floorspace in determining automation. Some machines maintain a smaller footprint with built-in automation.

Workpiece Size/Weight will define the machine size. Be aware that when machining 5 sides of a part one most look closely at fixtures and tool lengths when defining the machine to use. Matsuura or your Matsuura distributor can run a simulation using your solid model to confirm that the right size machine has been selected.

Machine Flexibility is a consideration for shops in their operations to satisfy different market segments and maintain the capability to produce different parts without major retooling. If your shop needs the ability to change a production schedule, to modify a part, or to handle multiple parts, then flexibility is vital.

According to St. John, the Aerospace Market is expected to grow substantially because of the long-term demand for airplanes. Low volume/high mix is the rule in the aerospace industry. Successful shops are already implementing small lot size automation and these innovative companies are he believes are hard to compete with using conventional approaches and conventional machines.

Matsuura’s customers often run the high-mix, low-volume components which require more engineering and set-up during the business day. Then, they change over to the unmanned production, where the pallets in the system run all night.

“Many companies claim that you can run three shifts, but with Matsuura you really can,” St. John concluded.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information about Matsuura, please contact: [email protected] or visit: www.matsuurausa.com.