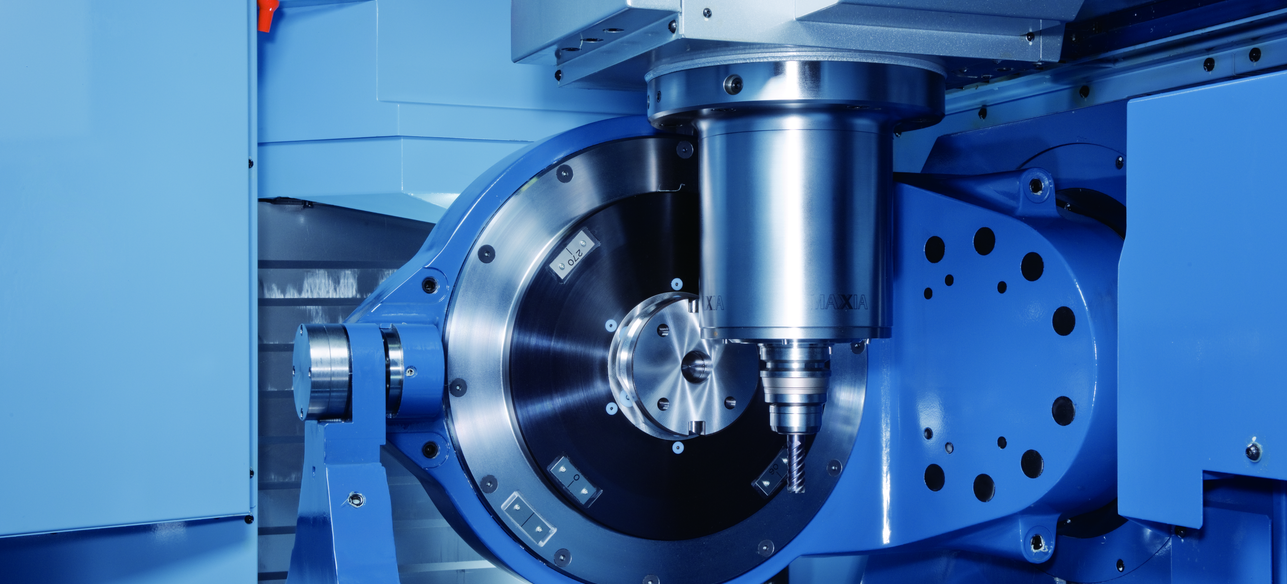

Partnering with Matsuura and Yamazen, Inc., Jergens Inc. has installed a MAM72-35V 5-Axis Vertical Machining Center at its 47-acre facility in Cleveland, Ohio. The MAM72-35V, equipped with a PC32 tower, 320 tools, a 20,000 RPM spindle, and a tailstock, is designed for long periods of unmanned operation.

Partnering with Matsuura and Yamazen, Inc., Jergens Inc. has installed a MAM72-35V 5-Axis Vertical Machining Center at its 47-acre facility in Cleveland, Ohio. The MAM72-35V, equipped with a PC32 tower, 320 tools, a 20,000 RPM spindle, and a tailstock, is designed for long periods of unmanned operation.

Jergens sought a flexible solution to maintain shorter lead times, competitive pricing, and consistent on-time delivery while meeting the growing demands of customers in a tight labor market.

“The flexibility of the machine itself has been fantastic for us. The 32 pallets have allowed us to put 5 different components in there at any given time and the flexibility to run during the day, as well as in the evening unattended,” said Randy Adams, Director of Operations and Sourcing for Jergens Inc. “We’re averaging at least 40 hours a week of unattended run, so the operator sets it up, he goes home, and the machine keeps on running for another eight hours, on average every day.”

The MAM72 series delivers process integration, complex 5-axis machining, and reliable extended unmanned operation. This enables variable-part, variable-volume production with precision and consistency.

Founded in 1942, Jergens Inc. is one of the world’s largest manufacturers of standard tooling components, vises, and workholding equipment. The company focuses on lean, efficient, and profitable manufacturing through innovation and engineering.

Adams shared that the Matsuura MAM72-35V helped Jergens adapt to workforce challenges and meet production targets. “We like everybody else struggle through some Covid issues and people being out, but the thing is, the machine is so simple to run once you’ve been able to do some training on it,” he said. “We’ve had other people come in and setup and run it, we had our supervisors and other operators come in to set this machine up on the weekend for unattended runs.”

He added, “We’re actually getting additional hours now, that in the past, we would have lost entirely. We’ve changed over our shifting strategies and added a 3-2-2 shift, where we’re running 7 days a week at least 12 hours a day.”

With 32 pallets and 320 tools, the MAM72-35V allows Jergens to minimize setup times and support multiple jobs seamlessly. “With 32 pallets and an average batch size of 5, and with 320 different tools in the tool changer, it allows us to have all the tools we need for any of the products we’re making,” Adams explained. “So, when you’re going from one job to another, you don’t have to stop and change out the tool and go back and forth.”

He continued, “More importantly, it allows us to set up redundant tooling, we have a secondary tool, a tertiary tool in there. During that unattended runtime, the machine can automatically go and grab that next tool and continue running, so you don’t lose just because a tool wears out or tool breaks.”

Jergens continues to push for efficiency and precision with Matsuura technology at the core of its automation strategy. “At Jergens, we have tried to stay on the cutting-edge and be a world leader, and you have to have sound equipment,” Adams said. “The Matsuura has fit that bill for us exactly.”

Learn more about Jergens Inc. at www.jergensinc.com.