Matsuura recently hosted the North American LUMEX Users Group Meeting at the company’s corporate headquarters in St. Paul, MN.

Matsuura LUMEX users from across North America participated in this event. Attendees at the Matsuura LUMEX Users Group Meeting had the opportunity to discover new LUMEX features & technology, share best practices in implementing the LUMEX technology, and participate in networking events that provided insight into industry trends. Attendees also participated in one-on-one learning sessions with Matsuura Application Engineers.

Attendees at the LUMEX Users Group also explored the Twin Cities and enjoyed an evening on a Mississippi Riverboat Dinner Cruise.

The Matsuura LUMEX Team thanks all those who attended and we look forward to hosting you again at the next LUMEX North America User Group Meeting.

Seminars and roundtable events included:

*Implementing LUMEX Technology Case Studies

*Implementing LUMEX for Rapid Tooling Development

*New Developments in Powders for LUMEX

*Machine Monitoring and Defect Detection System

*LUMEX CAM Software Features – Version 9 & 10

*LUMEX Machine Software Generation 5.1

*Bohler Uddeholm Corrax 3D & Dievar Material Characteristics

*Purdue University – Surface Finish Characterization

*Additive Manufacturing Simulation Machine DEMO–Fast Wire EDM

*Implementing Moldex 3D & Conformal Cooling

*Matsuura Remote Machine Monitoring System

For more information about this year’s LUMEX North America User Group Meeting , please contact: [email protected].

Matsuura’s LUMEX Technology is redefining the manufacturing process. The LUMEX series manufactures parts at near net shape, 3D objects with complex interior structures and creates components with hollows, 3D meshes and free-form surfaces. In addition, deep ribs, impossible to machine with machining centers, can be produced without using EDMs. This advanced technology is gaining attention not only in the die and mold industry but also in the aircraft and medical industries.

Metal laser sintering using a laser beam to melt powder and high-speed high-precision machining using end mills. These processes are repeated to produce the designed shape in one process on a single machine. Matsuura’s hybrid technologies achieve machining accuracy and surface finish comparable to machining centers, surpassing the capability of conventional metal 3D printers.

Matsuura’s LUMEX Technology can:

- Improve time to market

- Eliminate outsourcing expenses

- Address the skilled labor gap

- Use materials more efficiently for significant cost savings

- Reduce or Eliminate EDM and Polishing

- Build tooling in-house

- Decrease Mold Manufacturing Times

- Cut Cycle Times on high volume plastic injection parts

- Achieve True Lights Out Manufacturing

The Matsuura LUMEX was the first machine to combine the two jobs of forming and milling in a single unit. As a result, design and processing times that previously took two weeks to one month can be shortened by a third and costs can be reduced by up to half.

With multiple customer case studies, all showing 25% to 45% reductions in cycle time reductions, the Matsuura LUMEX Technology is transformative in the industry.

Matsuura’s LUMEX Technology relies on one-machine, one-process manufacturing of complex molds and parts by fusing metal laser sintering technology with high speed milling technology. The Hybrid technology creates a “finished” part with machined surface finish and accuracy, without inducing the additional variation caused by multiple machine set-ups and part handling.

With Matsuura’s Metal 3D Printing, the production of high-volume mold components with conformal cooling and integrated porous venting will minimize the need for traditional EDM processes, is a lights-out manufacturing system and provides significant time savings in the production of mold components.

Learn more by contacting: [email protected] or visit: HERE.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura LUMEX products, contact: [email protected].

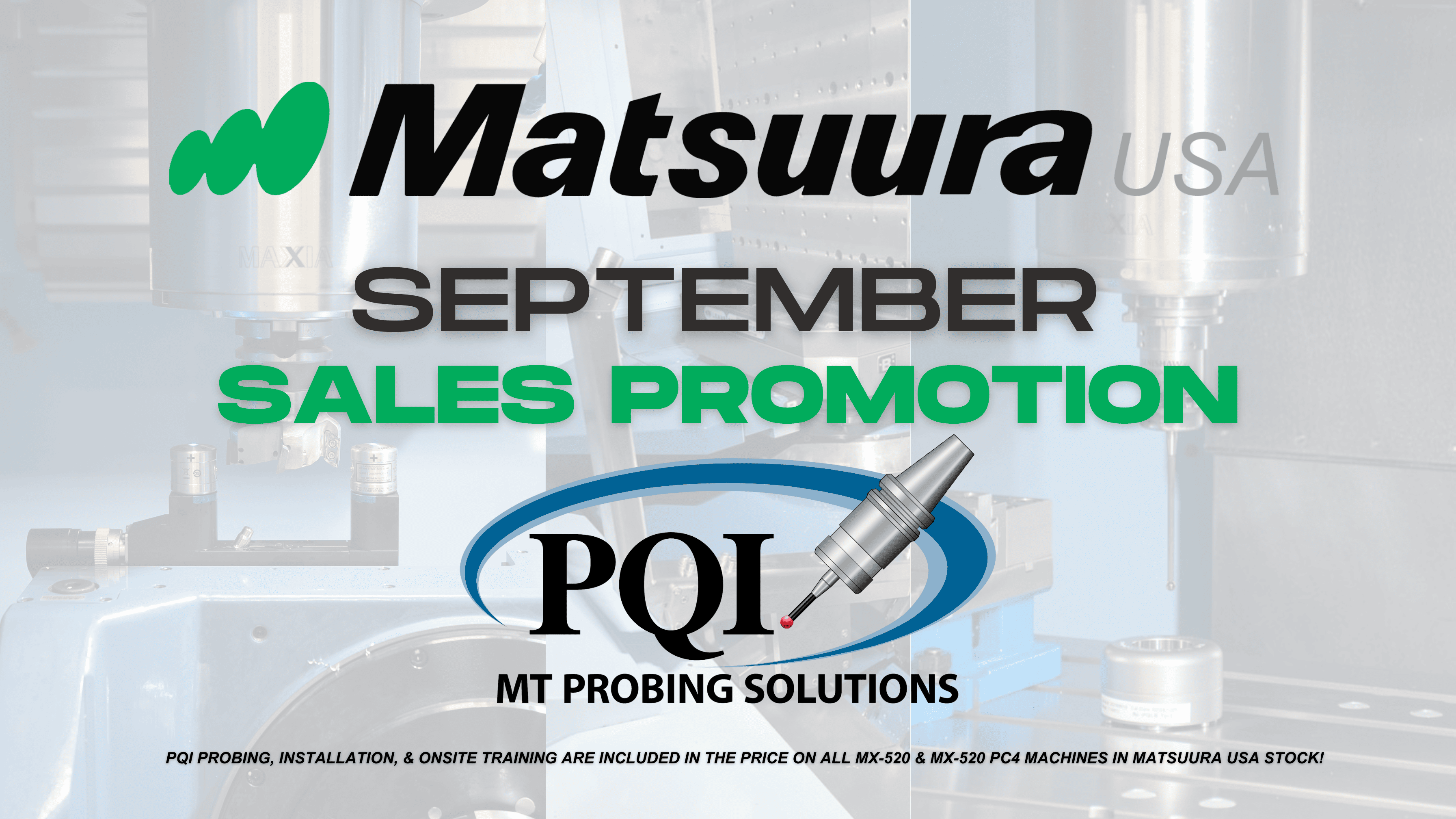

Don’t miss Matsuura’s September Sales Promotion! We are partnering with

Don’t miss Matsuura’s September Sales Promotion! We are partnering with