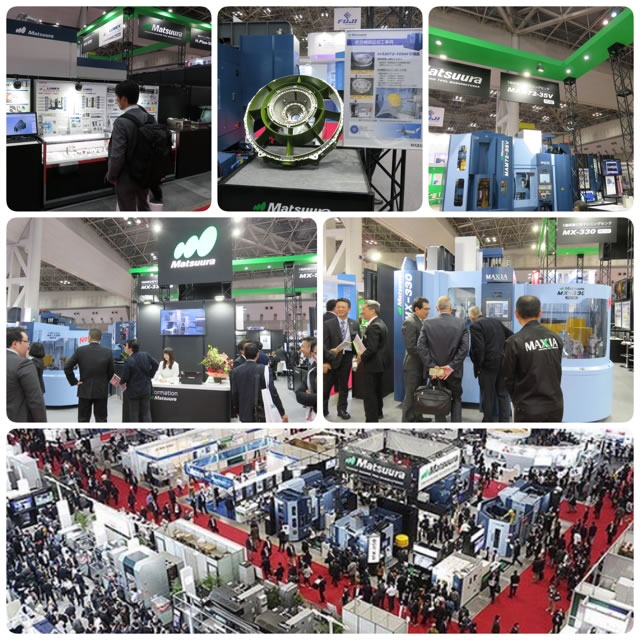

Tokyo (November 28, 2016) — Matsuura Machinery Corporation featured automation solutions and new technologies at this year’s Japanese International Machine Tool Fair at the Tokyo Big Sight exhibition grounds.

JIMTOF 2016, organized by the Japan Machine Tool Builders’ Association and Tokyo Big Sight Inc., is one of the largest machine tool exhibitions in Asia was recently held in November.

Matsuura Machinery exhibited the company’s latest technology at JIMTOF including the MX-330 5-Axis Vertical Machining Center with PC10 and the H.Plus-504, 4-axis Horizontal Machining Center. In addition, Matsuura showcased the MAM72-35V PC32, world-renowned for extended unmanned operation and the company’s established entry level 5-axis the MX-520 5-Axis Vertical machining Center.

“As a global leader in machine tool design and construction, Japan plays a key role in developing and promoting new metalworking technology. The Japan International Machine Tool Fair (JIMTOF) provides product introductions and educational opportunities at Tokyo’s eye-catching Big Sight exhibition center,” said a Matsuura Machinery USA Inc. Spokesperson.

JIMTOF has been held biennially since 1962 making JIMTOF 2016 the 28th edition of the exhibition. Products on display include machine tools (metal cutting and metal-forming), machine tool accessories, high speed steel tools, cemented carbide tools, diamond and CBN tools, grinding wheels and abrasives, gears and gear devices, oil and water hydraulic and pneumatic machinery, precision measuring machines and instruments, optical measuring instruments, testing machinery as well as CNC controls and related CAD/CAM software.

“JIMTOF is highly appreciated by industry participants from all around the world as a showcase that is among the first to introduce most advanced technologies,” the Matsuura Machinery USA Inc. Spokesperson added.

MX-330 5-AXIS VERTICAL MACHINING CENTER

After the significant global response to the MX-520 and MX-850 5-Axis Machining Centers, and market demand for a smaller MX Series 5 axis platform, the MX-330, configured with 10 pallets and 90 tools, provides affordable and reliable unmanned 5 axis production.

The all new MX-330 delivers machining center versatility with a standard Matsuura-made high accuracy spindle of 15,000 RPM with 48 ft-lbs. of torque. Optional 15,000 RPM with 88 ft-lbs. of torque and 20,000 RPM with 80 ft-lbs. of torque are available.

Ideal for the medical and aerospace industries and other high precision components, the MX-330 offers an easy transition from 3-Axis to 5-sided or 5-axis production. The MX-330 5-Axis Vertical Machining Center is excellent for small parts, but can handle parts up to ø13” X H11.8” and weighting up to 177 lbs.

The MX-330 is compactly built requiring floor space of only 6.1 ft. wide by 10 ft. long and ensures high-rigidity with a generous machining area and a table loading capacity of 177 lbs.

The machine’s maximum work envelope is D330 mm x H300 mm, with an optional D420 mm x H 300 mm. The MX-330 is designed with a RAM type structure, which offers a compact and highly durable machining platform. Available tool magazines include: standard 30 tool drum and optional 60 and 90 tool chains.

The MX-330 comes standard with a FANUC 31iMB with PANEL-I Control. The FANUC31iMB with PANEL-I Control is designed to be extremely user-friendly by making operating CNC machines easy and efficient.

H.PLUS-504 HORIZONTAL MACHINING CENTER

The Matsuura H.Plus horizontal machining centers are highly productive machine tools with high speed, rigidity, precision, reliability and low cost of ownership. The series delivers long periods of reliable, unmanned operation, high accuracy and exceptionally efficient production.

Since the series’ debut in 2000, over 1,700 Matsuura H.Plus machining centers have been installed worldwide in various industries, including: aerospace, aircraft, automobile, medical and precision subcontractors.

The H.Plus-504 is equipped with 500-by-500-mm pallet and #40-taper spindle. In response to customer and market demand for the accommodation of larger workpieces, the H.Plus-504 possesses the largest working envelope in its class and will handle a maximum workpiece size of D800 mm x H1,000 mm, weighing 750kg on each pallet.

In addition to the standard 12,000 min-1 spindle, a 20,000 min-1 (108.4 Nm) for high speed machining and 15,000 min-1 (350.0 Nm) for high-torque, heavy-duty machining are available.

A rotary indexing table (B axis) is provided as a standard feature, which is driven with a direct drive motor with a maximum feed rate of 100 min-1. In addition, Matsuura’s DCS (Dynamic Clamp System) and ADC (Automatic Acceleration and Deceleration Control) intelligently contribute to a shorter cycle and indexing time.

The expandable ATC/APC options enable extended unmanned operation: Tool storage capacity with a maximum of 330 tools (matrix type magazine) and pallet storage capacity with a maximum of 6 pallets (floor pallet system).

MAM72-35V 5-AXIS VERTICAL MACHINING CENTER

Incorporating decades of Matsuura expertise in machining center design and technology, the Matsuura MAM72-35V 5-Axis Vertical machining Center features high-accuracy complex five-axis machining with one-chucking to meet the need for cost-effective unmanned operation.

The Matsuura MAM72-35V has been the clear market leader for machines in its class for over two decades. The MAM72-35V is the solution for long periods of unmanned 5 axis simultaneous productivity.

The Matsuura MAM72 Series delivers long periods of unmanned productivity, and provides versatility in the machining of very small to very large components. Matsuura has a high performance MAM72 solution for every industry.

Enhancing cost-savings and providing better positioning with a maximum of two total setups, the MAM72-35V provides pallet and productivity solutions to keep your work center efficiently producing components around the clock. The Matsuura MAM72-35V offers an array of configurations from PC2 to Full Automation and Unmanned Running.

MX-520 5-AXIS VERTICAL MACHINING CENTER

Matsuura’s MX-520 Five-Axis Vertical Machining provides a simple, effortless and cost-effective transition for Three-Axis users making the transition to full Five-Axis operation. The MX-520 is a compact 5-Axis Vertical Machining Center featuring outstanding ergonomic design, which allows rapid set-up and processing of complex parts. CAMplete TruePath software – an integrated suite of G-code editing, optimization, analysis, and verification tools is standard.

With customers’ desire for reduced costs and improved cycle times, this compact 5-Axis Vertical Machining Center features rapid set-up and processing of complex parts, and is a cost-effective solution.

The Matsuura MX-520 guarantees high rigidity, as well as, a generous machining envelope with excellent operability. The MX-520 also offers an assortment of configurations, which are ideal for all applications, all industries and all materials.

Matsuura’s high-accuracy machining equipment, including multi-pallet and multi-tasking machine tools provides manufacturing solutions to a wide range of industries around the globe. Our automation proficiencies and automatic tool change abilities can simplify your production process, reduce cycle time and provide unmanned machining capabilities.

Matsuura Machinery USA, located in St. Paul, MN is the importer of Matsuura machining centers in the United States. Matsuura delivers unmatched excellence in high speed and high precision CNC machine tools. The company’s unmanned, high accuracy machining equipment, including multi-pallet and multi-tasking machine tools provide manufacturing solutions to a variety of industries around the globe.For more information on Matsuura products, contact: Matsuura Machinery USA, Inc.

[email protected]

www.matsuurausa.com