St. Paul, MN — (April 1, 2019) Matsuura USA will exhibit the Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine at North America’s largest additive manufacturing event, RAPID + TCT, in Booth 1903 at the Cobo Center in Detroit, Michigan, from May 20 – 23.

St. Paul, MN — (April 1, 2019) Matsuura USA will exhibit the Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine at North America’s largest additive manufacturing event, RAPID + TCT, in Booth 1903 at the Cobo Center in Detroit, Michigan, from May 20 – 23.

Over 400 exhibitors from across the 3D printing industry are included in RAPID + TCT 2019’s exhibitor list and more than 6,000 people expected to attend the show. This 3D printing event features over 110 technical presentations, a renewed focus on medical applications, plus an all-new automotive conference track.

“As one of the most influential events for additive manufacturing across the globe, RAPID + TCT is designed to drive industry change and disruption,” said Maria Conrado, SME’s senior event manager for RAPID + TCT.

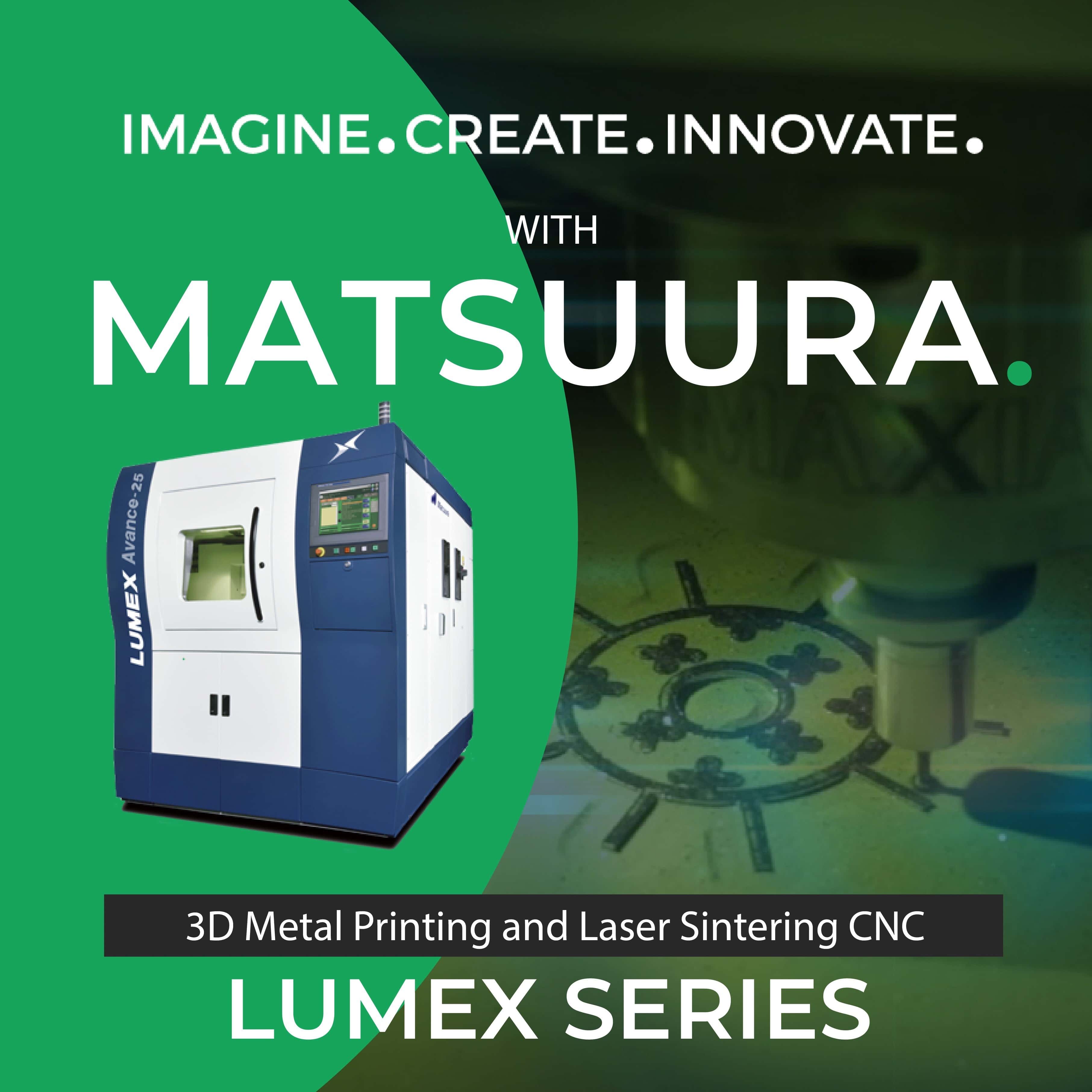

Matsuura will exhibit the Matsuura LUMEX Avance-25 metal laser sintering hybrid milling machine, a powder bed metal AM platform with subtractive machining capability in Booth 1903 at the event. The machine combines selective laser sintering (SLS) along with high speed milling (HSM) commonly called Hybrid AM.

“Matsuura LUMEX Technology has completely disrupted the part design paradigm. Instead of starting from a block or some other traditional geometric shape, the designer now can truly start with a blank page and ‘grow’ their designs for lightest weight, sleekest design, and most efficient use of material. The Matsuura LUMEX is truly creating freedom of design never before seen in the manufacturing world,” said Tom Houle, Director, LUMEX, NA, Matsuura Machinery USA, Inc.

Often referred to as a “one machine, one process” system, the Matsuura LUMEX series permits production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. These machines possess both high-speed milling and laser sintering capability.

The Avance-25 relies on one-machine, one-process manufacturing of complex molds and parts by fusing metal laser sintering technology with high speed milling technology. The Hybrid technology creates a “finished” part with machined surface finish and accuracy, without inducing the additional variation caused by multiple machine set-ups and part handling.

The Avance-25 achieves the highest accuracy in part fabrication since metal powders are melted and sintered via laser, while surfaces are precisely milled at high speeds. 3D cooling channels can be incorporated into molds in the single setup, thereby increasing cooling efficiency and enabling high-cycle injection molding with better than ever quality and precision, reducing costs and improving efficiency.

Matsuura’s combination of additive and subtractive technologies enables the production of parts and component geometries in a method that has never been possible or imagined. Often referred to as a “one machine, one process” system, the Matsuura LUMEX series permits production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. These machines possess both high-speed milling and laser sintering capability.

The Matsuura LUMEX Avance-25 is capable of processing parts and molds up to 256 mm x 256 mm x 185 mm with an option allowing processing of 256 mm × 256 mm × 300 mm. The Matsuura LUMEX Avance-25 serves predominantly the high value, high accuracy mold and die market. Dies and molds with very complex geometries can be fabricated in one piece with high accuracy, shortening lead time and reducing manufacturing costs to a half or even a third of conventional methods.

Differentiated original parts and mold production with internal structures, thus far considered impossible, are achievable on the Matsuura LUMEX Avance-25. The Matsuura LUMEX metal laser sintering hybrid milling machine is capable of quick turn production of custom parts and molds, whether prototypes or small production run parts and molds

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected].

St. Paul, MN — (March 27, 2019) Matsuura Machinery USA, Inc., announces the territory expansion of Yamazen, Inc. […]

St. Paul, MN — (March 27, 2019) Matsuura Machinery USA, Inc., announces the territory expansion of Yamazen, Inc. […]