St. Paul, MN (December 8, 2016) — Matsuura Machinery USA Inc. is offering year-end sales opportunities on the Matsuura MAM72-100H.

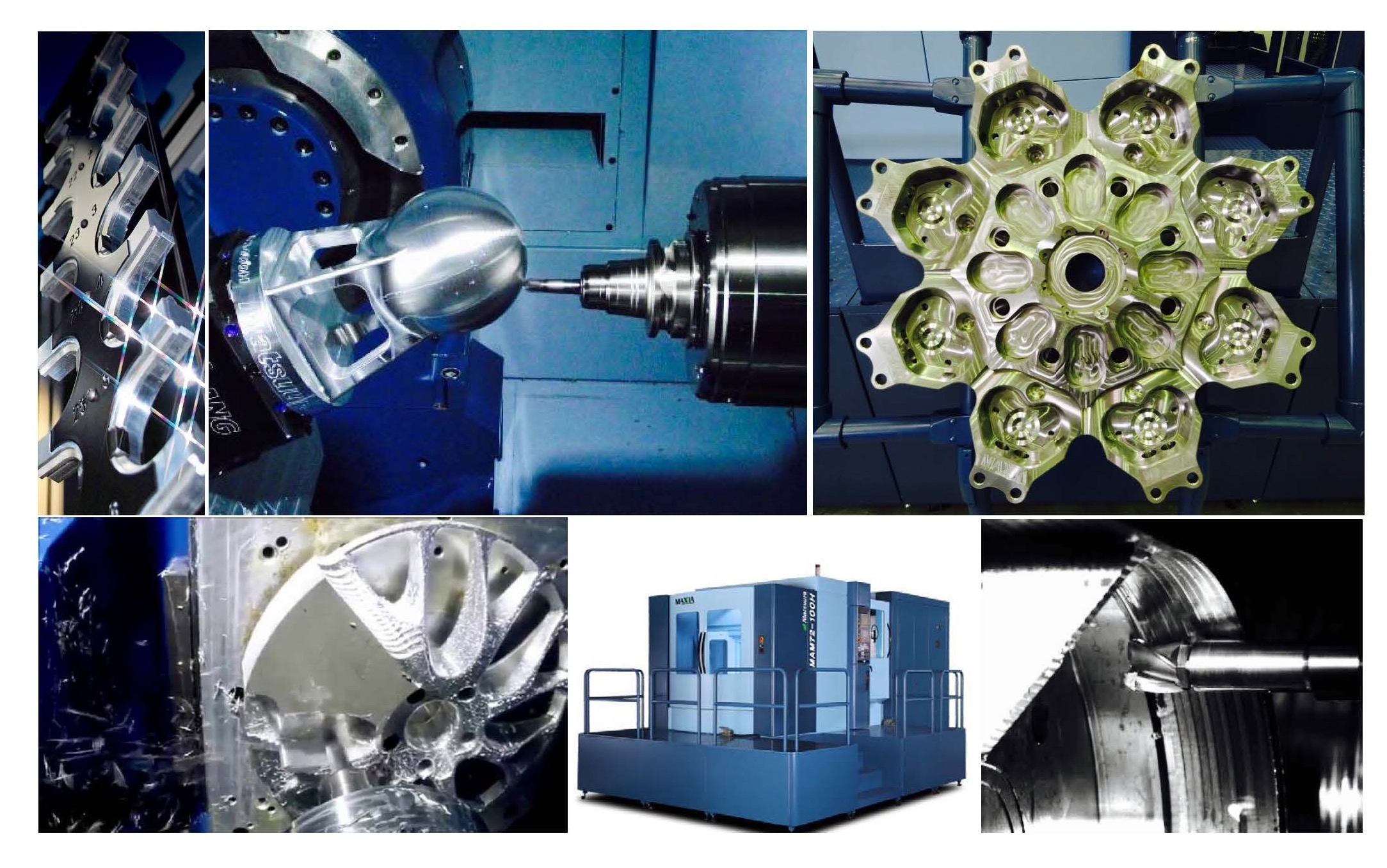

Designed in response to user requests for a MAM72 with a larger work envelope and even greater processing capacity, the MAM72-100H features x-y-z travels of 41.33″ x 36.22″ x 37.79″, an A-axis table that tilts between -120 and +30 degrees, and full 360 degree c-axis rotation. The A-/ B-axis table, with a direct drive motor, turns at a maximum feed rate of 50 minutes-1 (A-axis; Tilting axis) or 75 minutes-1 (B-axis; rotating axis), ensuring high speed and high precision. The MAM72-100H has the capability to handle a maximum work size of 39.37″ deep and 30.31″ high, and a maximum weight of 1,719 lbs. Equipped with a high-torque 50 taper spindle, the MAM72-100H is suitable for cutting hard-to-machine alloys, such as titanium and inconel.

The MAM72-100H features the next-generation Matsuura’s Intelligent Meister System (MIMS), which monitors the overall production process. MIMS ensures reliable operation, high product quality, simple data management and low power consumption. In addition, the automatic tool changer is equipped with a drum-type tool magazine driven by a servomotor for quick tool indexing, low noise and low vibration. A variety of ATC / APC options are also available.

“The MAM72-100H’s larger work envelope and ability to cut challenging materials makes it suitable for machining large-sized, complex parts that are common in the aerospace and energy industries. The MAM72-100H is the 5-axis machining platform solution for the production of close tolerance, extra-large components requiring long hours of reliable unmanned operation,” said a Matsuura Machinery USA Inc. Spokesperson.

The MAM72-100H five-axis horizontal machining center is the largest in the MAM72 series and is the company’s largest state-of-the art 5-axis manufactured in terms of capacity and size.

Like all of Matsuura’s five-axis machines, the MAM72-100H provides high quality, high speed simultaneous five-axis machining. Designed utilizing FEM analysis for maximum rigidity, the MAM72-100H offers a uniquely stable machining platform when compared to machines in its capacity class range. The MAM72-100H can process a wide array of materials and offers users advanced, proven unmanned operations.

“The MAM72 series is recognized for its reliable, high-speed, unattended machining. The MAM72-100H’s ability to machine larger parts makes it the definitive solution for aircraft, energy and other industries with larger machining requirements,” the Matsuura Machinery USA Inc. Spokesperson added.

The Matsuura MAM72-100H Five-Axis horizontal machining center allows cutting on all five sides in one operation and can achieve process integration and high-accuracy complex 5-Axis machining to meet the need for unmanned operation. This substantial machining center is one of very few to use linear motor, Five-Axis technology. The Matsuura MAM72-100H Horizontal Machining Center will be exhibited with the high-torque, #50 Taper Spindle.

Matsuura Machinery USA, located in St. Paul, MN is the importer of Matsuura machining centers in the United States. Matsuura delivers unmatched excellence in high speed and high precision CNC machine tools. The company’s unmanned, high accuracy machining equipment, including multi-pallet and multi-tasking machine tools provide manufacturing solutions to a variety of industries around the globe.

The company’s 40,000 sq. ft. facility includes a large showroom and demonstration area, conference and training rooms, machine storage areas, accessories and spare parts, as well as administrative, service, and engineering application support. A spindle repair facility is also currently being added.

Matsuura Machinery USA professionally markets and supports Matsuura equipment users through local distributors, making sure customers continue to have the high quality productivity solutions they require. From full five-axis, vertical, horizontal, linear motor or multi-tasking CNC machine tools, Matsuura has been the forerunner in designing innovative technology for the manufacturing industry.

Since 1935, Matsuura has been a leader in developing and manufacturing innovative machining equipment to ensure that manufacturing professionals always have the tools they need to create high quality parts. As the U.S. subsidiary of Matsuura Machinery Corporation in Japan, Matsuura USA provides the premium service, applications, and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura products, contact:

Matsuura Machinery USA, Inc.

[email protected]

www.matsuurausa.com