St. Paul, MN (October 10, 2018) — CMD-Custom Mold and Design (Forest Lake, MN) and Matsuura USA are collaborating in applying the Matsuura LUMEX technology for the mold industry. CMD will also offer contract Matsuura LUMEX production on the company’s LUMEX Avance-25 Metal Laser Sintering Hybrid Milling Machine, a powder bed metal AM platform with subtractive machining capability

Custom Mold and Design is the industry leader for designing and building high-precision, fast cycling molds, machine components and fixtures. The company serves a wide range of industries including medical, aerospace, consumer products and electronics. CMD offers a single source for molds, maintenance, fixturing and machined component needs.

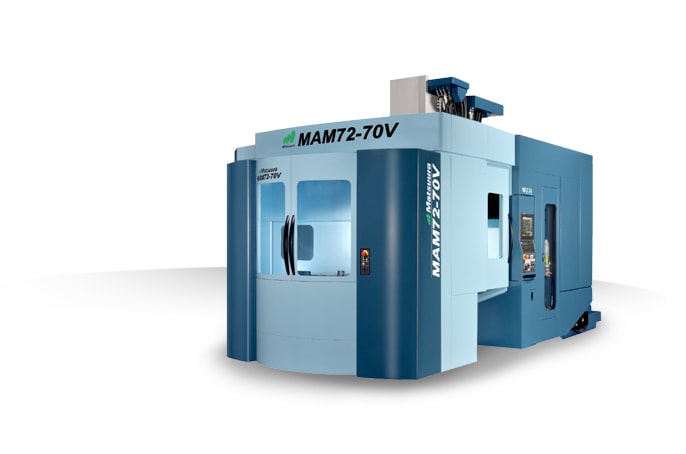

Often referred to as a “one machine, one process” system, the Matsuura LUMEX series permits production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. These machines possess both high-speed milling and laser sintering capability.

Matsuura’s combination of additive and subtractive technologies will enable Custom Mold and Design to produce parts and component geometries in a method that has never been possible, nor imagined.

“Matsuura’s cutting-edge technology is transformative in today’s world of 3D Metal Additive Manufacturing. With Matsuura’s combination of best-in-class CNC Milling and high-speed Direct Laser Melting, Matsuura has fundamentally revolutionized the AM marketplace,” Tom Houle, Director, LUMEX NA for Matsuura USA said.

“With CMD’s sustained performance of manufacturing molds since its foundation in 1965, their designers are extremely proficient with a dedicated interest in their customers’ needs. With the addition of the Matsuura LUMEX Avance-25, molds with complex geometries can now be fabricated in one piece with high accuracy, shortening lead time and reducing manufacturing costs by as much as a third over conventional machining technology,” Houle added.

3D cooling channels can be incorporated into molds on the Matsuura Avance-25 in the single setup, thereby increasing cooling efficiency and enabling high-cycle injection molding with better than ever quality and precision, reducing costs and improving efficiency.

“With the Matsuura LUMEX machine, CMD is now capable of leveraging AM’s on-demand manufacturing competencies and expanding flexibility, thereby producing higher quality mold,” Houle concluded.

Learn more about Custom Mold and Design at: custommold.net

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura LUMEX products, contact: [email protected] or visit: www.matsuurausa.com.

St. Paul, MN (October 5, 2018, 2018) — Matsuura USA is celebrating Manufacturing Day 2018 at the company’s headquarters in St. […]

St. Paul, MN (October 5, 2018, 2018) — Matsuura USA is celebrating Manufacturing Day 2018 at the company’s headquarters in St. […]