St. Paul, MN (October 15, 2020) – Founded in 2001, Rainhouse Canada, formerly Prototype Equipment Design (PED), has become an established force in the North American design and manufacturing industry.

St. Paul, MN (October 15, 2020) – Founded in 2001, Rainhouse Canada, formerly Prototype Equipment Design (PED), has become an established force in the North American design and manufacturing industry.

Rainhouse Canada, known for precise manufacturing, tight tolerances, and innovative solutions to their complex challenges, sought a 5-axis solution to minimize their multiple milling center setups.

Chris Lichty, lead machinist at Rainhouse Manufacturing Canada Ltd., was facing a problem, one that any machinist can relate to: too many setups and sought to perform their work in the most efficient manner possible. To Lichty, this means eliminating part handling, reducing work-in-process, cutting fixture costs and improving part quality, goals that most shops strive for, but fewer attain.

“It was a realization that many of our parts required six or even seven setups on a three axis vertical and, obviously, every setup means you have to re-fixture. This adds cost, not to mention the potential for errors and part inaccuracy. We could see that having a five axis would bring us to the next level, allowing us to pump out parts more quickly, be more accurate, and service our customers more effectively. That’s what brought us to the Matsuura.”

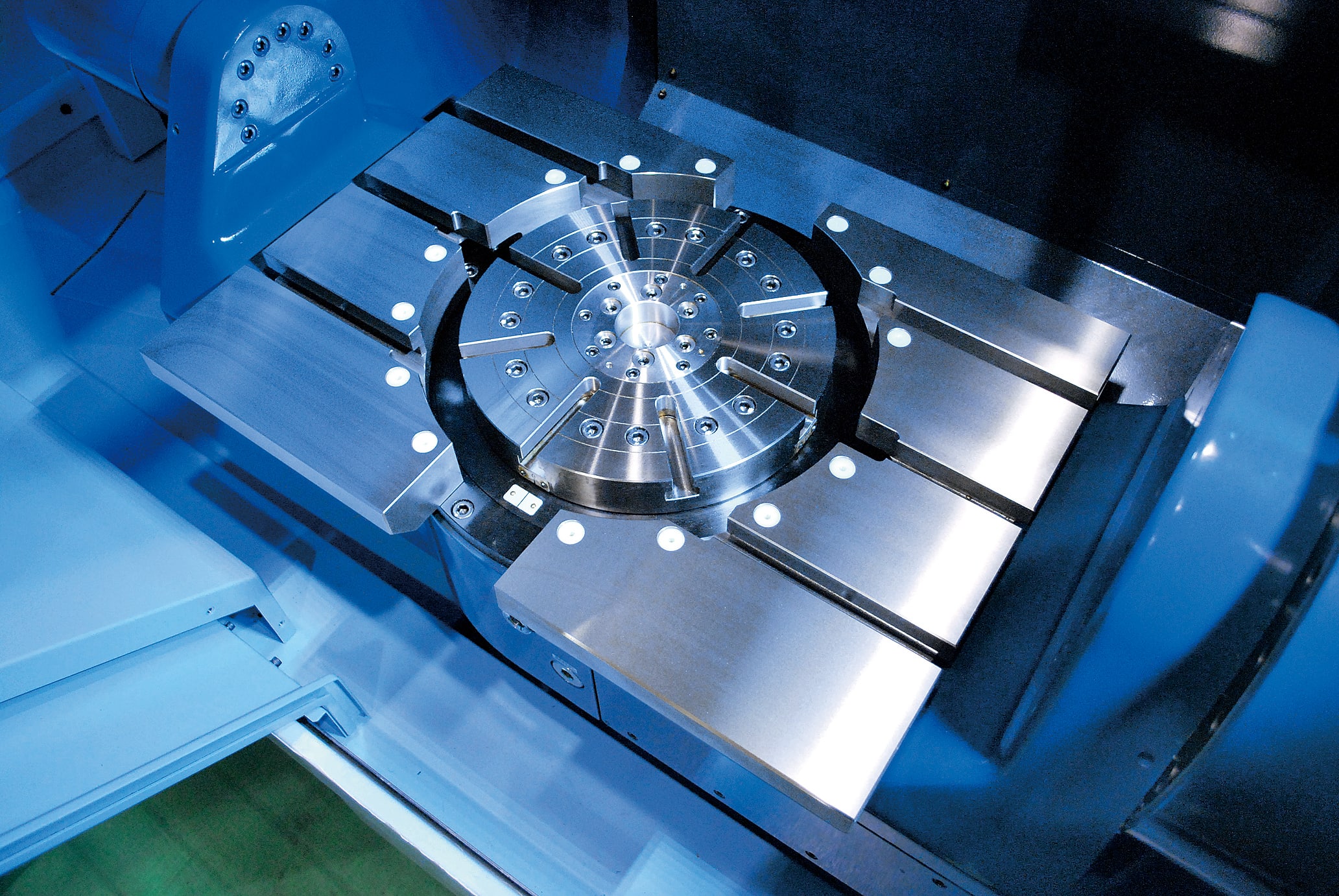

The Matsuura 5 axis machine has reduced setup times and increased throughput and efficiency at Rainhouse Manufacturing Canada.

There’s no shortage of challenging work at Rainhouse, but there are only so many hours in the day, which is why Lichty and president Ray Brougham decided to look at five axis machining to increase throughput and efficiency.

Rainhouse machines a variety of workpieces and materials on the MX-520, including a part they made recently for the forest industry. “It started out as a casting, and at that time it took us seven operations to complete the part,” he says. “The customer was having problems with breakage though, so asked us if we could make it from billet. As expected, when we bought the machine, we were able to complete the part in two operations, which not only took a bunch of cost out but greatly reduced the raw material lead-time.”

With high-precision, performance, speed, accuracy, and reliability, the MX-520 provides a simple, effortless and cost-effective transition for 3-Axis users making the transition to full 5-Axis operation. The MX-520 is the superior machine for high precision, high production applications, high mix/low volume, & expensive or difficult to machine materials.

Designed with a RAM type structure, which offers a compact and highly rigid machining platform. The machine guarantees high rigidity, as well as a generous machining envelope with excellent operability. The MX-520 also offers an assortment of configurations, which are ideal for all applications, all industries, and all materials.

The MX-520 has a compact footprint and outstanding ergonomic design, allowing rapid set-up and processing of complex parts.

The Matsuura MAXIA 12,000 RPM high-torque spindle is standard. A high-torque (187.0 Nm) motor is available to machine hard-to-cut materials. Matsuura’s 20,000 min-1 (108.7 Nm) spindle for high-speed machining of aluminum parts is available as an option.

CAMplete TruePath comes standard on all Matsuura 5-Axis Machines. The easy-to-use application that takes you from your CAM System to your Matsuura 5-Axis machine efficiently and safely. TruePath’s customizable post-processor allows you to output your NC programs the way you need, with no on-machine editing required. 5-axis simulation, visualization and verification tools give you the confidence of knowing how your machine will behave before you run a single line of G-code.

The Rainhouse engineering team collaborates on customer product designs and manages projects through to fruition, working with outside suppliers and contractors as needed, then assembling and testing the finished products in-house. The well-equipped machine shop mills, turns and EDMs everything from cadmium zinc telluride (CZT) to titanium, Inconel, PEEK, and Monel materials. Rainhouse also boasts surface mount (SMT) circuit board fabrication expertise using pick-and-place robots, a capability that traces back to the company’s roots in the medical imaging industry.

For his part, Brougham is quite pleased with the direction the MX-520 has taken his company, but what he especially likes about it is showing the machine to young people. That is because Rainhouse works with a number of educational groups and corporate sponsors to encourage manufacturing, including the University of Victoria, St. Margaret’s School for Girls, and a “high school robotics team” called FIX IT 3491. And just last year, Rainhouse joined forces with Babcock Canada, the local government, and others to promote and publicize competitions between local engineering students.

“Rainhouse represents an industrial manufacturing solution in a place where manufacturing doesn’t really exist,” he says. “Our goal is to raise awareness of what we do and to generate excitement about the trades. So, in addition to our work with the schools, we love to give tours of our facility to area residents and the one comment we consistently hear is, ‘I didn’t know you could do that here.’” He laughs. “People look at that five axis running out there and they’re just mesmerized by it. So, while the Matsuura has proven to be an excellent business decision for us, it’s also been quite educational…and a lot of fun besides.”

Portions from Shop Metalworking Technology: Kip Hanson, Images by Derek Ford, https://shopmetaltech.com/machining-technology/west-coast-wonder.html

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information about Matsuura, please contact: [email protected].