St. Paul, MN (October 9, 2019) —According to the Gardner Business Index (GBI), the The Moldmaking Index jumped nearly five points in September, driven by surging new orders.

St. Paul, MN (October 9, 2019) —According to the Gardner Business Index (GBI), the The Moldmaking Index jumped nearly five points in September, driven by surging new orders.

Moldmaking surged this September, reaching a high of 55.1, driven by a rush of new orders activity and followed by expanding production, backlogs and employment activity. In absolute terms, every component of the Moldmaking Index increased with only export activity reporting a sub-50 reading, indicating generally good news. The increase in the supplier delivery reading—marking a slowing in deliveries—is often considered a sign of strong demand for upstream moldmaking inputs; however, the presently inflated figures more likely represent the overwhelming disruption of supply chains caused by COVID.

A near 10-point advance in new orders activity was a substantial reason for the increase in the Index results. New orders readings above 50, which are also trending upward, signal that a growing proportion of survey respondents reported increasing new orders activity in September compared to August. The last time that new orders activity reported a similar reading was April of 2019.

September’s smaller expansion in production activity comes on the heels of a nearly 7-point increase in August. Should historical behaviors in the Index’s components prevail through the rest of 2020, the strong expansion in new orders this month could foretell expanding activity in the Index’s other metrics through the remainder of 2020.

New orders and production activity lead Moldmaking Index higher: A historical analysis of the Moldmaking Index and its components shows that new orders activity is often a bellwether for advances in the other components of the Index. Should this relationship hold in the coming months it could prove to be a boon to the Moldmaking lndex through year-end.

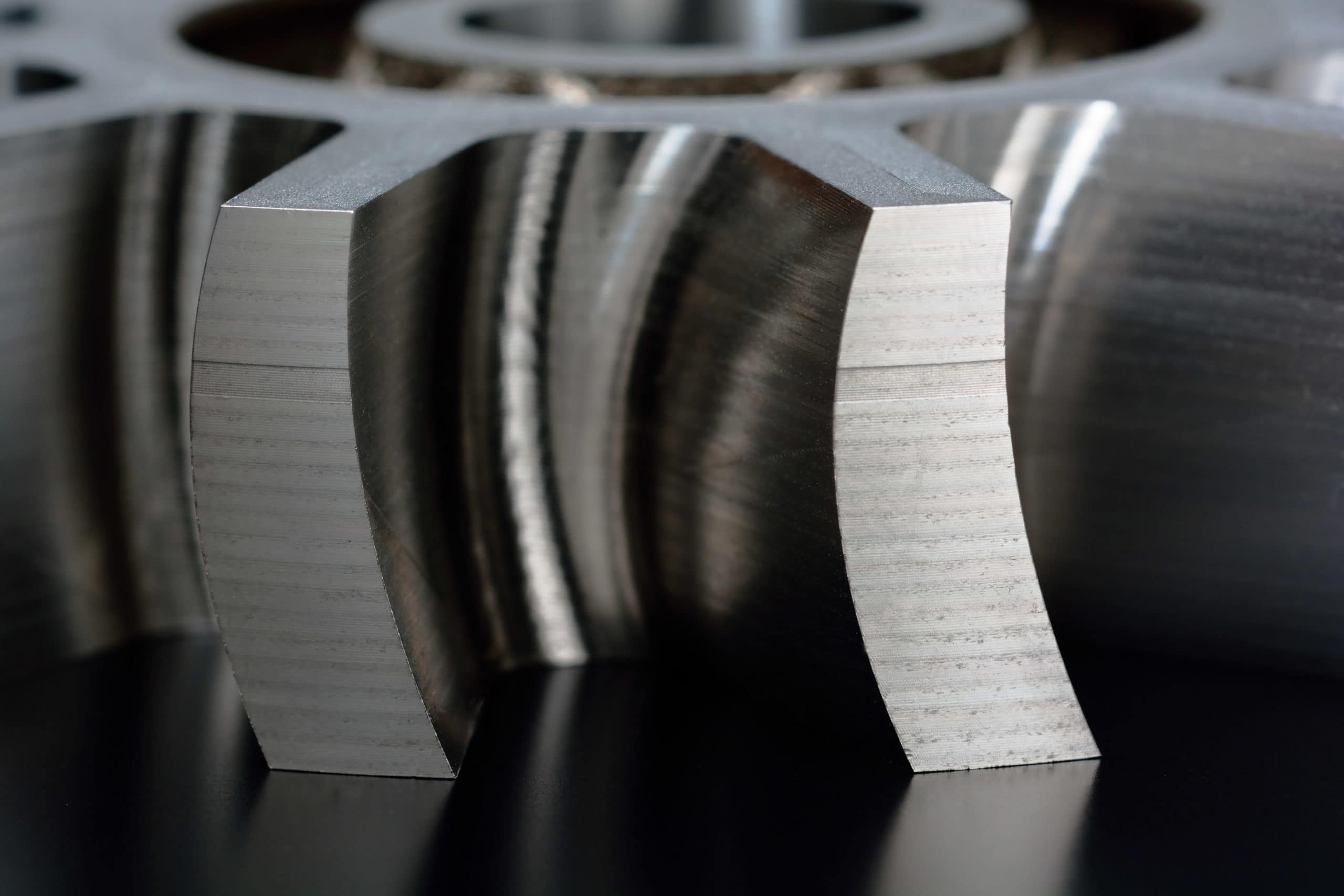

The Matsuura LUMEX Technology relies on one-machine, one-process manufacturing of complex molds and parts by fusing metal laser sintering technology with high speed milling technology.

Matsuura’s Hybrid additive/subtractive machining produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. This technology allows the ability to “grow” a metal component in layers with complex internal features and fine mill those internal features, as the layers are added, to give a perfect surface finish are what makes the LUMEX Series such a distinctive, unique and remarkable production platform and machine tool.

Matsuura’s technology is a proven solution for moldmakers. In most cases, the proper implementation of the hybrid technology in a mold component will eliminate the need for EDM. This in and of itself is a large time saver in the mold build process. Many components can be completely machined in the hybrid machine, there is an elimination of queue times to get other work completed on a component, typically reducing overall mold build time.

Please contact your exclusive Matsuura Distributor to discover how Matsuura’s Hybrid Additive Technology can revolutionize your manufacturing process.

More from Michael Guckes, Chief Economist & Director of Analytics, Gardner Intelligence, at: https://www.moldmakingtechnology.com/.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura LUMEX products, please contact: [email protected] or visit: matsuurausa.com.