With the rapid advancements in technology and processes, many organizations may consider investing in Matsuura’s 5-Axis automation solutions.

While some manufacturers outsource to reduce production costs, more progressive companies seek flexibility in their manufacturing processes to manage costs and expand their customer bases. This flexibility supports financial resilience in difficult economic times.

Automatically managing tools and pallets with software enables high-mix, low-volume production – where parts with a high value are produced on a single machining center – that can flexibly respond to the machining needs of the market.

True flexibility empowers manufacturers to stay in tune with their market, replacing rigid and static operating models with levels of control and responsiveness never previously possible.

Some advantages of High-Variation/Low-Volume production are better tailoring to specific customer demand, improved responsiveness and lower inventory requirements for finished goods.

In addition, High-Variation/Low-Volume companies can often take advantage of contract work for limited or small quantity product runs from High-Variation/Low-Mix companies, which may be either domestic or foreign.

This flexibility provides High-Variation/Low-Volume companies the ability to make investments and continue to grow. These companies adjust setup and processing procedures to create simplified workflows by implementing lean practices into assembly procedures. As a result, High-Variation/Low-Volume manufactures have become more capable of withstanding economic downturns and changes in market spending.

Matsuura’s automated, lights-out production enables many companies to take on low-volume jobs for various industries. With a wide variety of work, minimizing setup times is key to success.

An emphasis on quick changeover—the ability to quickly convert from running one product to another—is essential for a manufacturer that has a highly variable mix of product.

In small lot production, elimination of set-up time is the primary goal. Shaving a few seconds or even minutes of cycle time per part when making 20 or 30 parts is insignificant. The savings and the profit improvement come from reducing set-up time from hours to zero and by running parts unattended overnight and on weekends.

Matsuura Machinery has 30 years of 5-axis knowledge and experience combined with our more than 80-year heritage of innovative design, development and manufacture of high-quality machining centers.

Justifying new technology is a multi-step process that requires a thorough assessment of factors at work in your manufacturing operation. We can help you learn how to understand and evaluate the benefits and payback of Matsuura’s latest 5-axis technology.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

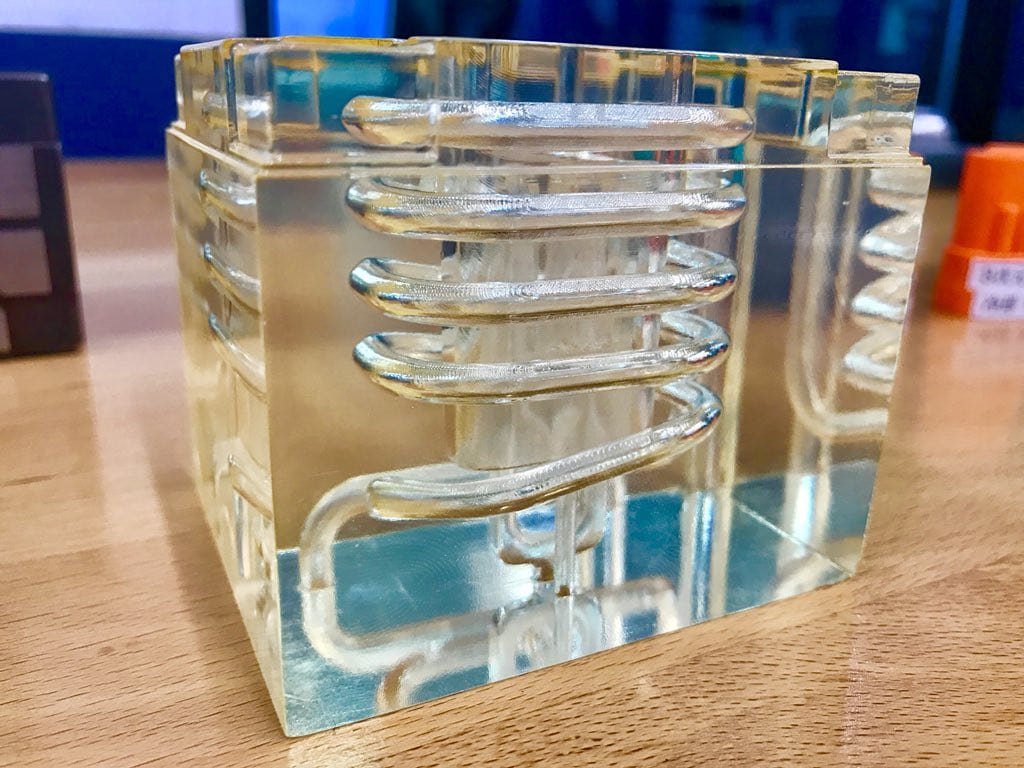

St. Paul, MN (July 23, 2020) — With Matsuura’s LUMEX technology, Deep Ribs and Conformal Cooling Channels significantly reduce product cycle time. […]

St. Paul, MN (July 23, 2020) — With Matsuura’s LUMEX technology, Deep Ribs and Conformal Cooling Channels significantly reduce product cycle time. […]